Tungsten is known for its high tensile strength and is one of the strongest metals. The tensile strength of tungsten is approximately 1510 megapascals (MPa), which is higher than many other commonly used materials such as steel and titanium.

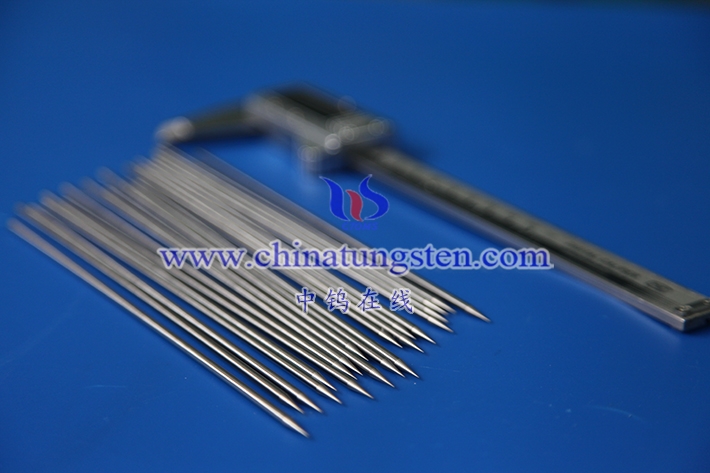

Tungsten needles, which are made from tungsten wire, inherit the high tensile strength of the material. However, the actual tensile strength of a tungsten needle can vary depending on its diameter, shape, and manufacturing process.

In general, tungsten needles are known for their strength and durability, and they can withstand high stresses and strains without breaking or deforming. This makes them well-suited for applications that require high precision and accuracy, such as micromanipulation, nanofabrication, and industrial manufacturing.

It is worth noting that while tungsten needles are strong and durable, they can still be damaged or deformed if subjected to extreme forces or misuse. As with any tool or instrument, it is important to use tungsten needles properly and handle them with care to avoid damaging them and compromising their performance.