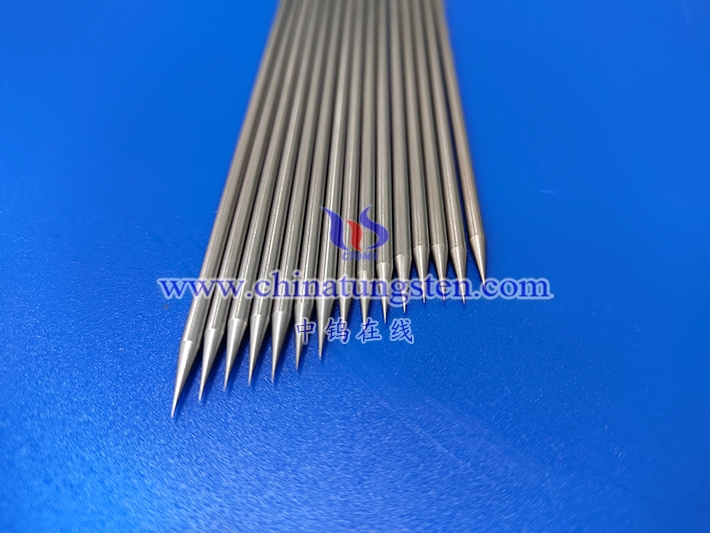

The manufacturing process for tungsten needles can have a significant impact on their performance. The process can affect the size, shape, and composition of the needles, as well as their mechanical and electrical properties.

The most common method for manufacturing tungsten needles is through a process called wire drawing. This involves pulling a tungsten wire through a series of progressively smaller dies to reduce its diameter to the desired size. This process can produce tungsten needles with high tensile strength and good ductility.

Other factors that can affect the performance of tungsten needles include the purity of the tungsten used, the annealing process used to relieve stress in the material, and any additional coatings or treatments applied to the surface of the needles. Overall, careful control of the manufacturing process is critical for ensuring consistent and reliable performance of tungsten needles.