Yes, tungsten needles can be used for microscale abrasion testing. Microscale abrasion testing is a widely used technique for evaluating the wear resistance of materials. In this technique, a small indenter, typically a needle or a ball, is used to create a controlled wear track on the surface of the material. The size and shape of the indenter, as well as the load and duration of the test, can be adjusted to mimic different types of wear encountered in real-world applications.

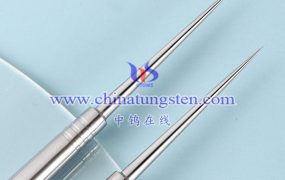

Tungsten needles are a good choice for microscale abrasion testing because of their high hardness, high strength, and excellent wear resistance. They can be easily machined into various shapes and sizes, including pointed tips for precise wear track generation. Additionally, tungsten needles have low coefficient of friction, making them less likely to cause unwanted scratching or damage to the sample surface during testing.