The refining process of molybdenum is mainly divided into two steps: extraction and refining.

Extraction of molybdenum

Most molybdenum minerals exist as oxidized molybdates, often in combination with other metallic elements. The extraction of molybdenum usually uses water cooling method or oxidation roasting method. The water cooling method obtains molybdenum oxide by mixing molybdenum ore powder with concentrated nitric acid, adding the mixture to cold water, and then precipitating and drying molybdate. Oxidation roasting exposes molybdenum ore to high temperatures, causing it to be oxidized to molybdenum oxide.

Molybdenum Refining

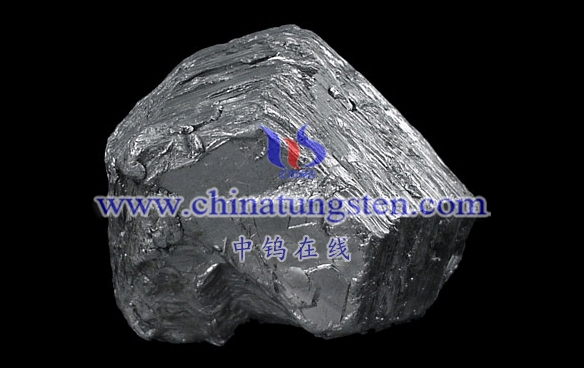

The refining of molybdenum oxide mainly uses the hydrogen reduction method, which is to mix molybdenum oxide with hydrogen and heat through a high-temperature furnace to reduce molybdenum oxide to pure molybdenum. During the reduction process, metallic molybdenum is separated from the oxide and molybdenum powder is formed. These molybdenum powders are often subjected to processes such as pressing and sintering in order to create a hard molybdenum block or sheet material for a variety of applications.

In short, the refining process of molybdenum requires the use of high temperature and high pressure conditions, as well as special chemical reagents and equipment.

More details of molybdenum or molybdenum products, please visit website: http://molybdenum.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of molybdenum products:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595