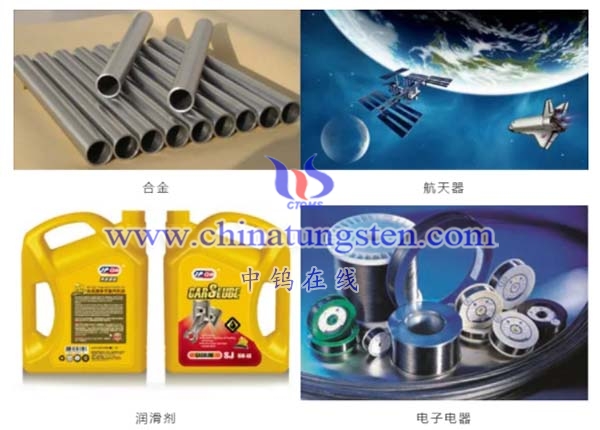

Molybdenum is widely used in the field of alloys, mainly for the improvement of strength, hardness, wear resistance, corrosion resistance and high temperature oxidation resistance. The following are some applications of molybdenum alloys:

Molybdenum steel alloy: Molybdenum steel is a high-strength, high-hardness, high-toughness and wear-resistant alloy, which is mainly used to manufacture mechanical parts such as knives, bearings, gears, and machine tools.

Molybdenum-copper alloy: Molybdenum-copper alloy has high thermal conductivity and good electromagnetic shielding performance, and is often used in the manufacture of high-temperature electronic components, radio frequency electronic components and semiconductor devices.

Molybdenum-tungsten alloy: Molybdenum-tungsten alloy has the characteristics of high melting point, high strength and high hardness, and is often used in the manufacture of high-temperature parts and corrosion-resistant parts, such as rocket nozzles, high-speed cutting tools, etc.

Ferro-molybdenum alloy: Ferro-molybdenum alloy can improve the strength, toughness and corrosion resistance of steel, and is often used in the manufacture of stainless steel, alloy steel and other materials.

Molybdenum-chromium alloy: Molybdenum-chromium alloy can improve the corrosion resistance and high temperature resistance of stainless steel, and is often used in the manufacture of equipment and pipelines in nuclear power plants, chemical, metallurgical and other industries.

In short, molybdenum alloys play an important role in industrial production, which can improve the performance and durability of materials and meet the needs of various complex working conditions.

More details of molybdenum or molybdenum products, please visit website: http://molybdenum.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of molybdenum products:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595