The production process of molybdenum alloy generally includes the following steps:

Raw material preparation: select appropriate molybdenum powder, other alloy element powders and additives, and mix them in a certain proportion.

Sintering: The mixed powder is sintered at high temperature into block or rod.

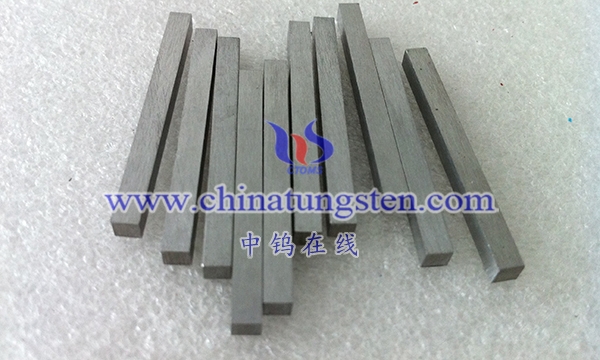

Thermal processing: The sintered block or rod is made into plates, rods, wires, etc. through thermal processing processes, such as hot rolling, hot extrusion, and hot stretching.

Cold processing: cold processing of molybdenum alloy materials formed by thermal processing, such as cold rolling, cold stretching, etc., to improve the strength and plasticity of the material.

Heat treatment: Carry out heat treatment on the molybdenum alloy material after cold working, including annealing, normalizing, quenching, etc., to adjust the structure and properties of the material.

Surface treatment: The surface of the molybdenum alloy material is treated by pickling, polishing, sandblasting and other methods to improve the surface quality and aesthetics.

Testing and packaging: testing of molybdenum alloy materials, including visual inspection, chemical composition analysis, mechanical performance testing, etc., and then packaging and labeling according to customer requirements.

More details of molybdenum or molybdenum alloy products, please visit website: http://molybdenum-alloy.com/index.html

Please contact CHINATUNGSTEN for inquiry and order of molybdenum alloy products:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595