In the production of new energy vehicles, the use of lithium battery anode materials containing yellow tungsten oxide can provide energy for power batteries and improve the cost performance of vehicles. As far as the new energy vehicle industry is concerned, the battery part is the core of the three electric technologies. According to relevant personnel, in 2019, the first batch of new energy vehicle battery systems with an energy density of more than 160Wh/Kg, a total of 15 models, are BYD, CITIC Guoan, GAC Group, JAC Huating, Ningde Times, Xingheng Power, Duo Fluoride, Tianjin Jiewei, Shanghai Delangeng, Ningbo Weirui. The battery systems they developed are all based on ternary batteries. Professionals pointed out that adding nano-yellow tungsten oxide to lithium battery anode materials in the production process can make the battery have a higher cost performance, thereby improving the international competitiveness of new energy vehicles. The reason why yellow nano tungsten oxide particles are used as the negative electrode material of lithium batteries is because yellow tungsten oxide has the advantages of high energy density and low price.

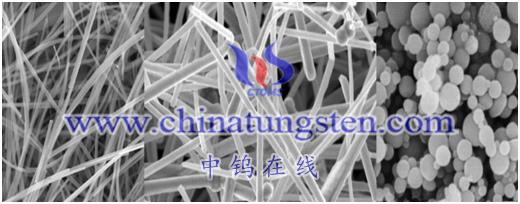

Nano-yellow tungsten trioxide, yellow tungsten, WO3 powder, is a special inorganic N-type semiconductor material, which can be used to prepare cost-effective electrode materials, that is, the prepared fast-charge lithium battery not only has high electrochemical performance , and lower production costs. Lithium batteries containing nano-yellow tungsten powder have wider uses than similar batteries in the market, and can provide sufficient energy for new energy vehicles, power tools, touch-screen mobile phones, notebook computers and other equipment.

Ternary lithium batteries and lithium iron phosphate batteries occupy the mainstream of the market. However, they have certain defects, such as limited space for increasing energy density. For this reason, scientists focus on the research on positive electrode materials and negative electrode materials.

Development Trend of Lithium Battery Cathode Material Technology

Materials such as orthosilicate, layered lithium-rich manganese-based, and sulfur-based cathodes are current research hotspots. Orthosilicate can theoretically allow the exchange of 2 Li+, and has a high theoretical specific capacity, but in the release process, the actual capacity is only half of the theoretical capacity. In addition to high specific energy, the layered lithium-rich manganese base also has the advantage of reasonable price. It is necessary to find a suitable production method. Although the sulfur-based cathode material has an energy density as high as 2600Wh/kg, it is prone to volume expansion during the charging and discharging process, which needs to be improved.

Development Trend of Lithium Battery Anode Material Technology

Graphene, lithium titanate, and nano-yellow tungsten oxide are the anode materials for lithium batteries with high research and development enthusiasm. Graphene can be used as a positive and negative electrode conductive agent, combined with positive and negative electrode materials to form a composite material, but it cannot be used as a positive and negative electrode active material to replace graphite-based negative electrode materials in large quantities. Lithium titanate has a long cycle life, which can reach more than 10,000 times, and can be charged quickly. It is more suitable for energy storage fields that do not require space. Nano-yellow tungsten oxide is a special electrode material with a theoretical capacity of 693mAh/g, excellent electrochromism, low price, abundant reserves, and non-toxicity.

In summary, nano-yellow tungsten oxide WO3 can be used as an electrode material and used in new energy vehicles.

More details of tungsten oxide product, please visit website: tungsten-oxide.com

Please contact CHINATUNGSTEN for inquiry and order of tungsten oxide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595