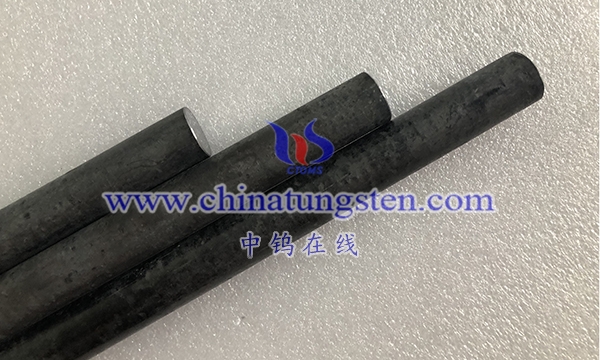

TZM alloy rod is a high-temperature alloy material composed of the acronyms of titanium (Titanium), zirconium (Zirconium) and molybdenum (Molybdenum). It is also known as titanium zirconium molybdenum alloy rod. TZM alloy rods have excellent high-temperature mechanical properties and corrosion resistance, so they are widely used in high-temperature environments.

TZM alloy rods are usually prepared by mixing titanium, zirconium and molybdenum in a certain proportion, and then performing powder metallurgy or vacuum melting. It has a high melting point, high strength, high hardness and excellent heat resistance. Therefore, TZM alloy rods are often used as structural materials for high-temperature equipment and tools, especially for aerospace, aeroengines, nuclear engineering and other high-temperature applications.

The application range of TZM alloy rods includes the manufacture of high-temperature furnaces, electrodes, electronic devices, vacuum furnace parts, spark processing electrodes, high-temperature melting furnaces, etc. Its advantages include high temperature resistance, oxidation resistance, corrosion resistance and high strength, which can maintain stable performance in extreme environments.

It should be noted that although the TZM alloy rod has many advantages, its price is relatively high and the preparation process is relatively complicated. Therefore, specific application requirements and economics need to be considered comprehensively when selecting materials.

More details of molybdenum or molybdenum alloy products, please visit website: http://molybdenum-alloy.com/index.html

Please contact CHINATUNGSTEN for inquiry and order of molybdenum alloy products:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595