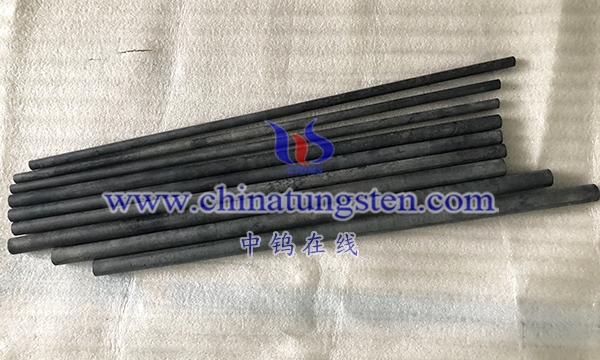

A common method of preparing TZM alloy rod is powder metallurgy (powder metallurgy) technology, the specific steps are as follows:

Raw material preparation: Mix titanium powder, zirconium powder and molybdenum powder evenly according to the required element ratio.

Mixing: Put the mixed powder into a ball mill jar and mix it through a ball mill to ensure the uniformity of the powder and the fineness of the particles.

Compression: Put the mixed powder into a mold for high-pressure compression. Commonly used pressing methods include isostatic pressing and die pressing.

Sintering: put the pressed powder body into a high temperature furnace for sintering. During sintering, the powder particles are combined by heating to form a dense alloy body.

Finishing: The alloy rod is finely processed by machining, grinding, polishing and other processes to meet the final size and surface requirements.

More details of molybdenum or molybdenum alloy products, please visit website: http://molybdenum-alloy.com/index.html

Please contact CHINATUNGSTEN for inquiry and order of molybdenum alloy products:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595