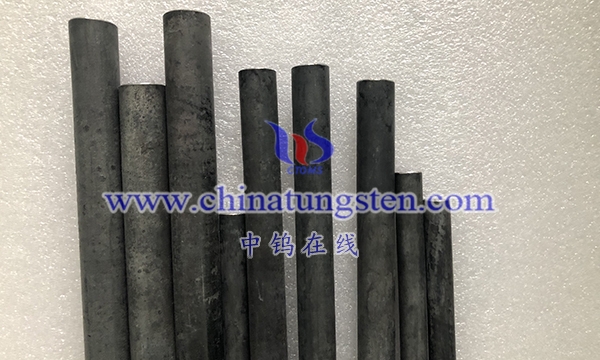

Compared with other materials, TZM alloy rods have the following advantages:

High-temperature strength: TZM alloy rods have excellent high-temperature strength and high-temperature hardness, can maintain good mechanical properties in high-temperature environments, and have excellent resistance to deformation and thermal fatigue.

Corrosion resistance: TZM alloy rods have good corrosion resistance, exhibit excellent corrosion resistance in both oxidizing and reducing environments, and can resist the erosion of some acids, alkalis and salt solutions.

High melting point: The composition of TZM alloy rod contains molybdenum element, which makes it have a high melting point, can maintain stable performance under extreme high temperature conditions, and is not easy to melt or deform.

Excellent thermal conductivity: TZM alloy rods have high thermal conductivity, which can effectively transfer heat and are suitable for high-temperature heat transfer fields.

Good processing performance: TZM alloy rods can be formed and processed by conventional metal processing methods, such as forging, rolling, drawing, etc., which are convenient for manufacturing parts of various shapes and sizes.

Stable performance: TZM alloy rods have stable physical and chemical properties, are not prone to material failure, corrosion, deformation and other problems, and can work stably in high temperature and corrosive environments for a long time.

More details of molybdenum or molybdenum alloy products, please visit website: http://molybdenum-alloy.com/index.html

Please contact CHINATUNGSTEN for inquiry and order of molybdenum alloy products:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595