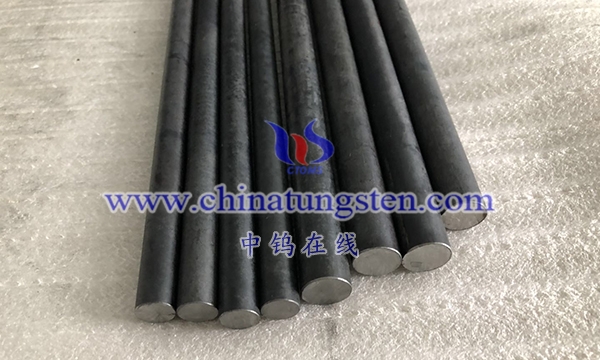

TZM alloy rods and MHC alloy rods are two different alloy materials, and they have some differences in composition, properties and applications. Here are the main differences between them:

Composition: TZM alloy rods are mainly composed of three elements: molybdenum (Mo), titanium (Ti) and zirconium (Zr), among which the content of molybdenum is the highest, usually above 99%. The MHC alloy rod is a molybdenum-niobium alloy, mainly composed of molybdenum (Mo) and niobium (Nb), and the content of molybdenum is relatively high.

Strength and hardness: Due to the difference in composition, TZM alloy rods are relatively high in strength and hardness, and have excellent mechanical properties. While MHC alloy rods are slightly lower than TZM alloy rods in terms of strength and hardness, but still have good mechanical properties.

High temperature resistance: Both TZM alloy rods and MHC alloy rods have good high temperature resistance and can maintain good stability in high temperature environments. However, due to differences in composition, their high temperature performance may vary.

Corrosion resistance: Both TZM alloy rods and MHC alloy rods have good corrosion resistance and can show high stability in many corrosive media. Specific corrosion resistance may be affected by composition and environment.

Application fields: TZM alloy rods are often used in high-temperature structural parts and components in aerospace, nuclear energy, chemical and other fields. MHC alloy rods are often used in electronic devices and smelting equipment in high temperature environments.

It is necessary to select the appropriate alloy material according to the specific application requirements and material characteristics. Both TZM alloy rods and MHC alloy rods are high-performance materials with their own advantages and scope of application.

More details of molybdenum or molybdenum alloy products, please visit website: http://molybdenum-alloy.com/index.html

Please contact CHINATUNGSTEN for inquiry and order of molybdenum alloy products:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595