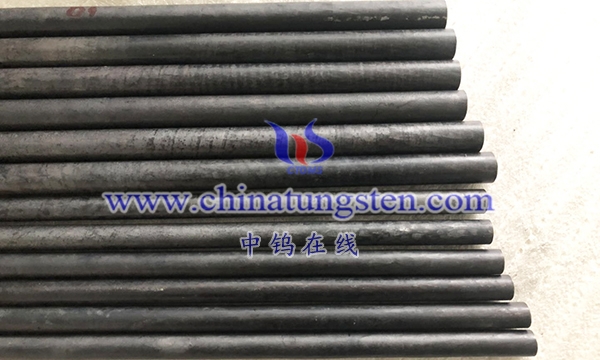

TZM alloy rods and molybdenum-rhenium alloy rods are two different alloy materials, and they have some differences in composition, properties and applications. Here are the main differences between them:

Composition: TZM alloy rods are mainly composed of molybdenum (Mo), titanium (Ti) and zirconium (Zr), among which molybdenum has the highest content. The molybdenum-rhenium alloy rod is composed of molybdenum (Mo) and rhenium (Re), and the content of rhenium is relatively high.

Strength and hardness: Due to the difference in composition, TZM alloy rods are relatively high in strength and hardness, and have excellent mechanical properties. Molybdenum-rhenium alloy rods have higher strength and hardness, but may be slightly lower than TZM alloy rods.

Thermal expansion coefficient: The thermal expansion coefficient of TZM alloy rod is low, which makes it have better thermal stability in high temperature environment. Molybdenum-rhenium alloy rods have a relatively high coefficient of thermal expansion, which may cause greater thermal expansion when the temperature changes.

Corrosion resistance: Both TZM alloy rods and molybdenum-rhenium alloy rods have good corrosion resistance and can exhibit high stability in various corrosive media. Specific corrosion resistance may be affected by composition and environment.

Application fields: TZM alloy rods are often used in high-temperature structural parts and components in aerospace, nuclear energy, chemical and other fields. Molybdenum-rhenium alloy rods are commonly used in high-temperature structural parts and electrode materials in aerospace, electronics, chemical and other fields.

More details of molybdenum or molybdenum alloy products, please visit website: http://molybdenum-alloy.com/index.html

Please contact CHINATUNGSTEN for inquiry and order of molybdenum alloy products:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595