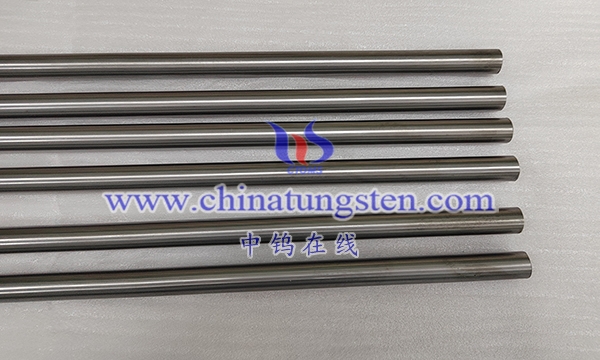

The main application of TZM alloy rod is to use it on the hot runner nozzle. On the basis of the original standard TZM, the composition ratio, hardness and strength are readjusted to make the TZM alloy rod more stable and wear-resistant in the hot runner nozzle core. To ensure that users in the hot runner industry use the process more efficiently and increase production capacity.

The hardness of the TZM alloy rod is above HRC23, while the hardness of the conventional TZM rod is HRC18-20; at the same time, the comprehensive performance of the TZM alloy is improved, so that the recrystallization of the TZM alloy at high temperature is not embrittled, more wear-resistant, and has better resistance to carbon fiber and glass fiber. High corrosion resistance. At the same time, the TZM hot runner nozzle does not leave gate residues on the product and the marks at the gate are smooth. It can speed up the filling of gate and cavity with larger diameter, effectively reduce injection pressure and product deformation, and prevent stringing and salivation during mold opening. When the screw of the injection molding machine retreats, it can effectively prevent the material from being sucked back from the mold cavity; it can cooperate with sequence control to reduce the occurrence of product weld marks.

TZM alloy material is the best material for processing hot runner nozzles. The recrystallization of TZM alloy at high temperature is much superior to that of pure molybdenum, which effectively avoids the possibility of embrittlement under high temperature use. Of course, the price of TZM is also higher than that of pure molybdenum, because TZM alloy has better strength, corrosion resistance, elongation performance, and superior thermal conductivity; it makes the product less likely to deform and crack.

TZM molybdenum alloy rods play a key role in the injection molding hot runner industry. The stable service life and wear resistance of the hot runner nozzle/nozzle core can effectively improve the user’s production efficiency, save plastic raw materials, and reduce and shorten the cost of accessories.

More details of molybdenum or molybdenum alloy products, please visit website: http://molybdenum-alloy.com/index.html

Please contact CHINATUNGSTEN for inquiry and order of molybdenum alloy products:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595