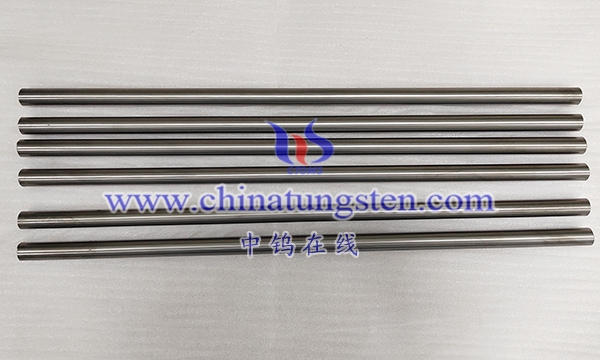

TZM alloy rods can be used in electrical discharge machining (Electrical Discharge Machining, referred to as EDM). EDM is a method of material processing through electric pulse discharge, which is often used to process materials with high hardness and good wear resistance, such as metal alloys.

TZM alloy rod is composed of tungsten, zirconium and molybdenum, which has good electrical and thermal conductivity, making it one of the suitable materials for EDM. In EDM, by applying a voltage between the surface of the workpiece and an electrode, the workpiece is melted and etched in an instantaneous spark discharge to achieve precise shape machining.

TZM alloy rods exhibit excellent discharge stability and wear resistance in EDM, can withstand high energy density EDM, and maintain a long processing life. Its high melting point and high temperature resistance also make it resistant to material melting or deformation caused by high temperature during EDM.

More details of molybdenum or molybdenum alloy products, please visit website: http://molybdenum-alloy.com/index.html

Please contact CHINATUNGSTEN for inquiry and order of molybdenum alloy products:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595