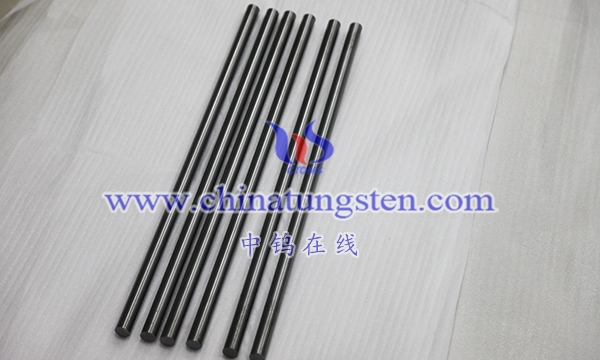

In hot runner nozzles, TZM alloy rods are usually used as the manufacturing material for the nozzles. The following are some characteristics of the application of TZM alloy rods in hot runner nozzles:

High temperature resistance: TZM alloy rod has excellent high temperature strength and heat resistance, and can withstand thermal load and thermal shock in high temperature environment.

Corrosion resistance: Since the composition of the TZM alloy rod contains molybdenum, it has good corrosion resistance and can resist the erosion of many corrosive media, including corrosion in high temperature environments.

High thermal conductivity: TZM alloy rods have high thermal conductivity, which can effectively conduct heat and help heat management and heat dissipation of hot runner nozzles.

Low coefficient of thermal expansion: TZM alloy rod has a low coefficient of thermal expansion, which is closer to many substrates with low coefficient of thermal expansion than many other materials, reducing stress and deformation caused by thermal expansion mismatch.

Processing performance: TZM alloy rod has good machinability, and can be formed and processed by thermal processing (such as forging, rolling) and mechanical processing (such as turning, drilling) to meet the complex shape of the hot runner nozzle and size requirements.

More details of molybdenum or molybdenum alloy products, please visit website: http://molybdenum-alloy.com/index.html

Please contact CHINATUNGSTEN for inquiry and order of molybdenum alloy products:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595