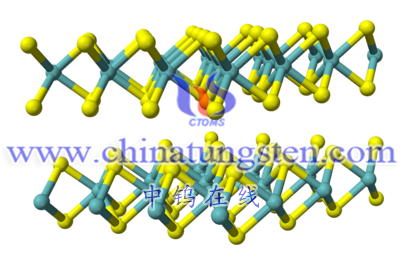

Molybdenum disulfide (MoS2) is an important solid lubricant, known as the “king of solid lubricants”

Molybdenum disulfide is a solid powder made from natural molybdenum concentrate powder after chemical purification. The color of the product is black with silvery gray, metallic luster, greasy feeling to the touch, insoluble in water. The product has the advantages of good dispersion and no sticking. It can be added to various oils to form a colloidal state that will never stick, increasing the lubricity and extreme pressure of the oil; it is also suitable for high temperature, high pressure, high speed, high speed The mechanical working state of the load prolongs the life of the equipment; the main function of molybdenum disulfide used in friction materials is to reduce friction at low temperature, increase friction at high temperature, and have a small loss on ignition.

Molybdenum disulfide (MoS2) is widely used as a good solid lubricant, and the following working conditions are applicable:

- Lubrication under wide temperature conditions: the application range of lubricating oil and grease is about 60°C to 350°C. Molybdenum disulfide solid lubricants can be used in the working temperature range from ¬270°C to 1000°C.

- Lubrication under heavy load conditions: the oil film of general lubricating oil and grease can only bear relatively small loads. Once the load exceeds the limit value it can bear, the oil film will break and the friction surfaces will bite. The average load that the solid lubricating film can bear is 108Pa.

- Lubrication under vacuum conditions: under high vacuum conditions, the general lubricating oil and grease are highly evaporative, which is easy to damage the vacuum environment and affect the working performance of other components. Molybdenum disulfide solid lubricating materials are generally used for lubrication.

- Lubrication under radiation conditions: Under radiation conditions, general liquid lubricants will polymerize or decompose and lose their lubricating properties. Solid lubricants have better radiation resistance.

- Lubrication of conductive sliding surfaces: friction of conductive sliding surfaces such as motor brushes, conductive sliders, solar collector rings and sliding electrical contacts on artificial satellites working in vacuum can be made of carbon graphite or metal Lubricated composite materials.

- Occasions with very harsh environmental conditions: occasions with harsh environments, such as transportation machinery, engineering machinery, metallurgical and steel industry institutions, mining machinery and other transmission parts working in harsh environments such as dust, sand, high temperature and humidity, can be used Molybdenum disulfide solid lubricant for lubrication.

- Occasions in corrosive environments: For example, transmission parts such as ship machinery and chemical machinery work in corrosive media such as water (steam), sea water, acid, alkali, and salt, and must withstand different degrees of chemical corrosion. The transmission parts working in this situation can be lubricated with molybdenum disulfide solid.

- Occasions where the environmental conditions are very clean: MoS2 solid lubricants can be used for lubrication of transmission parts in electronics, textiles, food, medicine, papermaking, printing and other machinery to avoid pollution.

- Occasions that do not require maintenance: some transmission parts do not need maintenance, and some transmission parts need to reduce the number of maintenance in order to save costs. In these occasions, the use of MoS2 solid lubricants is both reasonable and convenient and can save money.