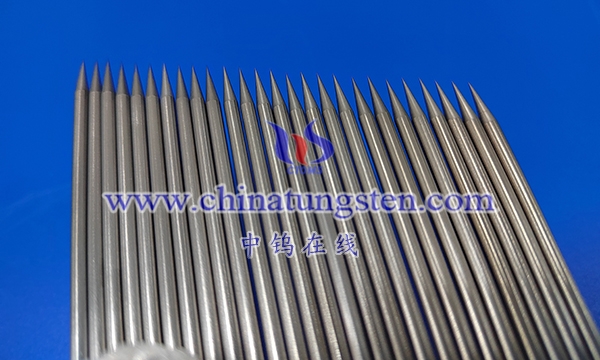

In many applications, the surface finish of tungsten steel needles is very important. Here are some reasons:

Contact performance: When tungsten steel needles are used to detect, pierce or contact other materials, the smoother surface can reduce friction and resistance and provide better contact performance. Smooth surfaces help ensure stable electrical connections, precise measurements, and reliable transmission and sensing.

Cleanability: Smooth surfaces are easier to clean and can reduce the adhesion of impurities and dirt. In some applications, such as medical instruments or laboratory equipment, it is critical to keep the surface of the tungsten carbide needle clean to ensure accurate measurement results or to avoid cross-contamination.

Corrosion resistance: The smooth surface helps to improve the corrosion resistance of tungsten steel needles. Corrosion can cause surface roughness, oxidation, or other adverse effects that can affect the performance and life of tungsten carbide needles. By keeping the surface smooth, the corrosion resistance of the tungsten steel needle can be improved and its service life can be extended.

Accuracy: In some applications, such as precision machining, tip probing, or microelectronics manufacturing, the surface finish of tungsten carbide needles is critical to achieving high precision and high quality results. Smooth surfaces reduce errors and deviations, ensuring accurate machining, measuring and probing.

More details of tungsten needles, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595