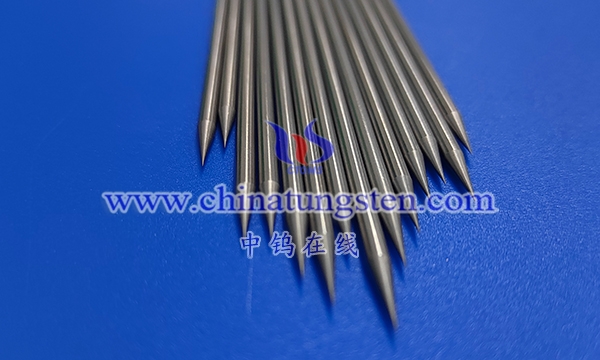

The manufacturing process of tungsten carbide needles can be divided into the following steps:

Selection of raw materials: Select high-purity tungsten powder and other metal powders as raw materials, after screening and mixing, put them into the quartz boat.

Hot isostatic pressing: Put the quartz boat into a hot isostatic press, and press tungsten powder and other metal powders into shape through high temperature and high pressure.

Sintering: put the pressed tungsten steel body into a sintering furnace, and carry out high-temperature sintering treatment, so that the tungsten steel body reaches a certain density and firmness at high temperature.

Precision machining: The sintered tungsten steel body is surface polished and precision machined to make tungsten carbide needles that meet the requirements.

The manufacturing process of tungsten carbide needles is relatively complicated, and factors such as temperature, pressure, and processing time need to be carefully controlled throughout the process to ensure that the quality and performance of the final product meet the requirements.

More details of tungsten needles, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595