Due to its high strength, high hardness and wear resistance, it is widely used in the manufacturing and testing process of electronic components. Here are some specific applications:

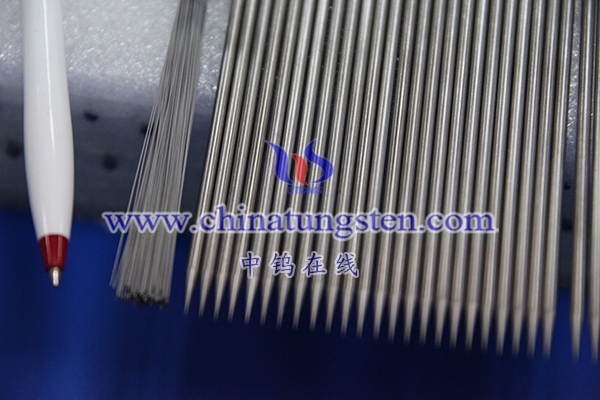

Manufacturing Test Probes: Test probes are used to check the electrical performance of circuit boards and other electronic devices. Tungsten carbide needles are used as the test probe material with high wear resistance and sharpness, which can penetrate the surface coating and ensure reliable electrical connection.

Manufacturing integrated circuit leads: Tungsten carbide pins are used to manufacture integrated circuit leads to provide high reliability for connecting devices. Its high strength and wear resistance make it stable under high temperature and pressure.

Fabrication of electrodes: Tungsten carbide needles can be used to fabricate tiny electrodes, such as those in scanning tunneling microscopes. Its high electrical conductivity and corrosion resistance make it an ideal material for these applications.

Manufacture of metal compound gas sensors: Tungsten carbide needles can be used to make micro heaters in metal compound gas sensors. Due to its high melting point and high temperature resistance, tungsten carbide needles can withstand high temperature heating and produce stable temperature control.

More details of tungsten needles, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595