As an industrial material, molybdenum electrodes need to meet certain quality standards during production and use. The following is one of the common quality standards for molybdenum electrodes:

Chemical composition: The chemical composition of the molybdenum electrode should meet the relevant standards. In general, high-purity molybdenum electrodes have high chemical composition requirements and need to meet specific element content and impurity limits.

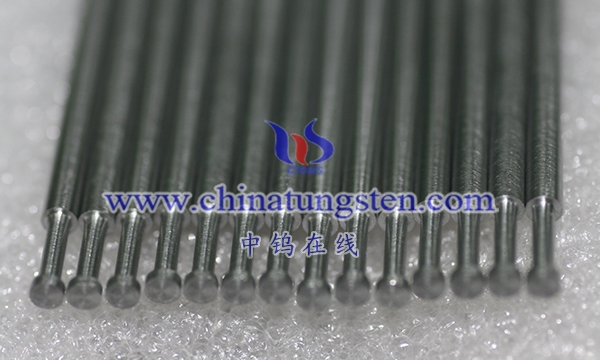

Size and shape: The size and shape of molybdenum electrodes should meet design requirements or industry standards. Including the control of diameter, length, flatness, straightness and other parameters.

Surface quality: The surface of the molybdenum electrode should have a certain degree of smoothness and flatness to ensure good contact and electrical conductivity. Surfaces may need to be polished, cleaned, etc. to meet requirements.

Conductivity: Molybdenum electrodes should have good conductivity, including low resistance, high conductivity and stable conductivity.

These quality standards can vary according to specific application areas and customer needs. Suppliers or manufacturers usually implement strict quality control during the production process and provide relevant quality certification documents, such as chemical analysis reports, dimensional inspection reports, and performance test reports, to ensure that the quality of molybdenum electrodes meets the requirements.

More details of molybdenum or molybdenum alloy products, please visit website: http://molybdenum-alloy.com/index.html

Please contact CHINATUNGSTEN for inquiry and order of molybdenum alloy products:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595