The basic process of obtaining ammonium metatungstate by thermal dissociation method is:

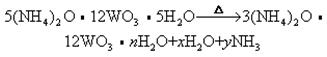

Heating APT makes it lose part of ammonium and water, and converts it into ammonium metatungstate which is easily soluble in water. The reaction is:

n, x, y in the formula vary with temperature. The most important process parameter in the process is the temperature of thermal dissociation. If the thermal dissociation temperature is too high and the time is too long, a large amount of APT will be decomposed into tungsten trioxide; otherwise, a large amount of APT will be incompletely transformed. The thermal dissociation temperature is generally controlled between 503 ~ 543K, the time is 1 ~ 5h, and the conversion rate can usually reach more than 95%. The simple way to check the thermal dissociation products is to take out a representative sample and analyze the WO3 content in it. Those within the range of 90.5% to 92.5% are qualified, those less than 90.5% should be returned to the furnace for further dissociation, and those greater than 92.5% should be dissociated. Transfer to tungsten trioxide production process. If unqualified thermal dissociation products are leached out, a milky feed solution will be obtained. This kind of feed liquid is difficult to clarify and filter, and will reduce the yield of ammonium metatungstate.

The thermal dissociation products were leached out with deionized water, and the liquid-solid ratio was 7.5:1. Boil the leach solution for 1 hour under stirring conditions, and keep the pH of the solution between 3.0 and 4.0 during the process. Wait for the feed liquid to cool and clarify to obtain a transparent supernatant, and then filter to remove the insoluble residue.

The obtained ammonium metatungstate solution is concentrated, crystallized or spray-dried. During the concentration process, the pH of the solution should be kept between 3.0 and 4.0, otherwise APT or tungstic acid will be precipitated. When it is concentrated to a density of 1800-2400kg/m3, it can be cooled and crystallized or spray-dried to produce ammonium metatungstate product. The quality of the ammonium metatungstate produced by this method is good, and the process is stable and reliable. It only needs to add one or two sets of equipment to the APT production line, and the problems of process, raw materials and waste can be easily solved.

More details of ammonium metatungstate product, please visit website: http://ammonium-metatungstate.com/

Please contact CHINATUNGSTEN for inquiry and order of ammonium metatungstate:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595