The production process of molybdenum rods usually includes the following steps:

Preparation of molybdenum powder: First, molybdenum trioxide (MoO3) with high purity is obtained through the processes of ore extraction and ore smelting. Molybdenum trioxide is then reduced to metallic molybdenum powder, usually using hydrogen as the reducing agent.

Molybdenum powder processing: The obtained molybdenum powder is sieved and finely processed to obtain the desired particle size and purity. These steps help to eliminate impurities and improve the quality of molybdenum rods.

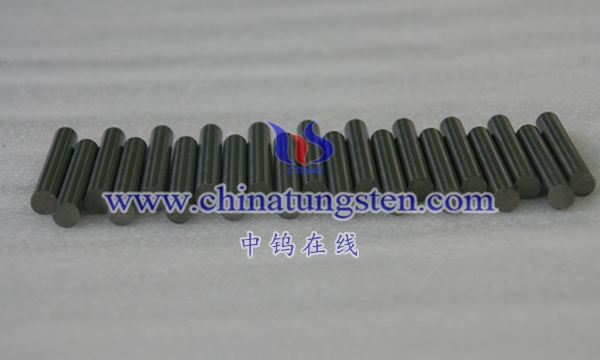

Molybdenum rod preparation: Molybdenum powder is pre-pressed and pressed to form a rod-shaped molybdenum billet. Cold isostatic pressing or hot isostatic pressing is usually used to ensure high density and consistent structure of molybdenum billets.

Sintering and annealing: The pressed molybdenum billet is sintered, usually at high temperature. During the sintering process, the molybdenum powder particles are combined to form dense molybdenum rods. Next, through the annealing process, the internal stress is eliminated and the mechanical properties of the molybdenum rods are improved.

Processing and trimming: After sintering and annealing, the molybdenum rods are finely processed and trimmed. This includes cutting, turning, grinding and other processes of molybdenum rods to obtain the required size and surface quality.

Inspection and quality control: Strict inspection and quality control are carried out on molybdenum rods during the production process. This includes testing the size, density, purity and mechanical properties of molybdenum rods to ensure that the products meet the specified standards and requirements.

More details of molybdenum or molybdenum alloy products, please visit website: http://molybdenum-alloy.com/index.html

Please contact CHINATUNGSTEN for inquiry and order of molybdenum alloy products:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595