Molybdenum rods are relatively easy to machine into different sizes. Because molybdenum has good plasticity and workability, it can be processed into various sizes and shapes through appropriate processing methods.

The following are some common processing methods that can be used to process molybdenum rods into different sizes:

Cutting: Using a cutting tool such as a saw blade or secant, cut the molybdenum rod to the desired length.

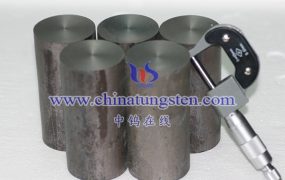

Grinding: The molybdenum rod is ground to the desired size using a grinder or grinding wheel to either diameter or length.

Drilling: Use a drill press or drill to drill holes in the molybdenum rods to obtain the desired hole diameter and depth.

Turning: Turning operations are performed on molybdenum rods using lathes and cutters to machine them to the desired diameter and length.

More details of molybdenum or molybdenum alloy products, please visit website: http://molybdenum-alloy.com/index.html

Please contact CHINATUNGSTEN for inquiry and order of molybdenum alloy products:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595