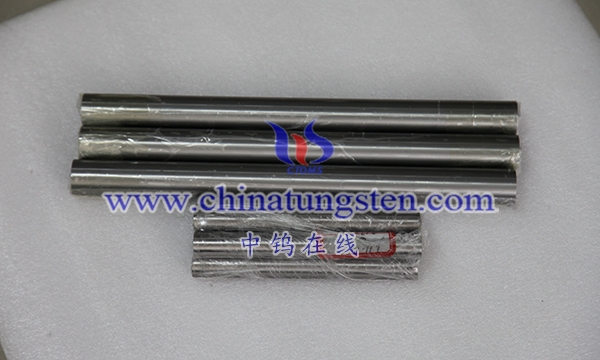

Molybdenum rods are recyclable materials. Because of its high melting point, high strength and corrosion resistance, molybdenum is an important material widely used in many industries. When molybdenum rods are used for a certain period of time, they can be reused by recycling and reprocessing, thereby reducing the demand for raw materials and environmental impact.

The recycling process of molybdenum rods usually includes the following steps:

Collection and sorting: The recycling process usually begins with the collection of spent molybdenum rods. The waste molybdenum rods will be sorted, sorted and arranged for subsequent treatment and reprocessing.

Smelting and purification: Waste molybdenum rods are usually sent to smelting plants for smelting and purification. In this process, the waste molybdenum rods will be heated to a high temperature to melt the molybdenum material, and remove impurities by physical or chemical methods to obtain high-purity molybdenum material.

Reprocessing: The smelted and purified molybdenum material can be reprocessed into molybdenum rods of different shapes and sizes to meet specific application requirements. Reprocessing can include cutting, forging, extrusion, heat treatment and other processes.

More details of molybdenum or molybdenum alloy products, please visit website: http://molybdenum-alloy.com/index.html

Please contact CHINATUNGSTEN for inquiry and order of molybdenum alloy products:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595