Molybdenum rods are widely used in electrical discharge machining (EDM). EDM is an unconventional machining method that uses electrical discharges to process conductive materials, and is often used to manufacture complex shapes, fine structures, and high-precision parts. The following are the applications of molybdenum rod in EDM:

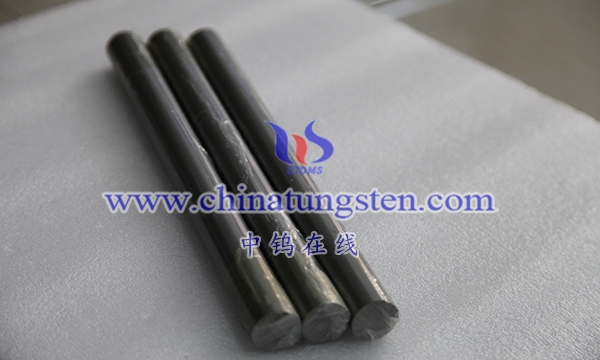

Electrode material: Molybdenum rods are often used as electrode materials in EDM to generate discharge pulses. Molybdenum’s good electrical conductivity, high melting point and wear resistance make it an ideal electrode material of choice.

Manufacture of complex shapes: Molybdenum rods can be precisely cut into required shapes and sizes to meet the requirements of complex parts. Its high hardness and wear resistance enable molybdenum rods to maintain a long service life during EDM, thereby achieving higher machining efficiency.

Microstructure processing: Due to the high hardness of molybdenum rods and the controllability of microstructures, it can be used to manufacture tiny holes, fine grooves and microstructures. This is very important for some microfabrication applications, such as microelectronic devices, microfluidic devices and precision molds.

High-precision machining: The stability and precision of molybdenum rods make them ideal for high-precision machining. It can be used to process high-precision molds, templates and tooling to meet strict dimensional and surface quality requirements.

More details of molybdenum or molybdenum alloy products, please visit website: http://molybdenum-alloy.com/index.html

Please contact CHINATUNGSTEN for inquiry and order of molybdenum alloy products:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595