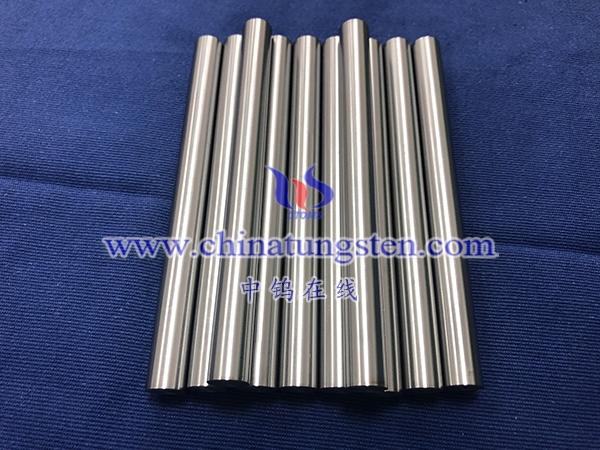

Molybdenum rods are used in a variety of applications in the glass industry, the following are some common application areas:

Glass Melting Furnaces: Molybdenum rods can be used as heating elements in glass melting furnaces. In the glass production process, high temperature melting furnaces require a stable and long-lasting heating source. Because of its excellent high temperature stability and corrosion resistance, molybdenum is often used as heating wires, heating rods or heaters in glass melting furnaces.

Fiberglass Manufacturing: Molybdenum rods play an important role in the fiberglass manufacturing process. Fiberglass is a commonly used insulating material, widely used in construction, electronics, aerospace and other fields. Molybdenum rods are used in the stretching mechanism in the glass fiber production line to ensure uniform stretching and formation of fibers.

Optical Fiber Manufacturing: Optical fibers are an essential part of modern communications and optical technology. Molybdenum rods are used in drawing mechanisms and heating elements in the fiber drawing process. Its high temperature stability and mechanical strength ensure fiber quality and uniformity.

Vacuum coating: Vacuum coating technology is often used in glass products to provide special optical effects, reflective properties or protective layers. Molybdenum rods are used as heaters and support rods in vacuum coating equipment to provide stable heating and support functions.

Glass processing tools: Molybdenum rods have high hardness and wear resistance, and can be used in the production of glass processing tools. For example, molybdenum rods can be used as cutting tools, fiberglass blades and grinding tools for machining and handling glass products.

More details of molybdenum or molybdenum alloy products, please visit website: http://molybdenum-alloy.com/index.html

Please contact CHINATUNGSTEN for inquiry and order of molybdenum alloy products:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595