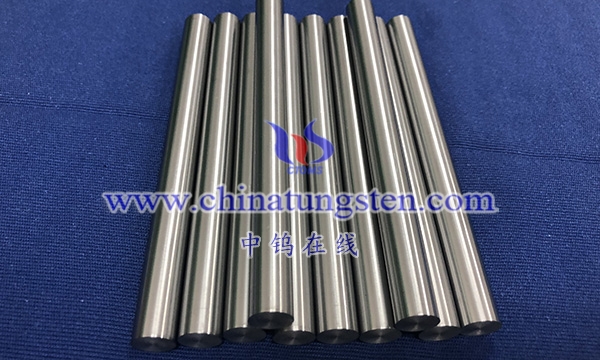

Molybdenum rods are often used in the manufacture of precision instruments and equipment. Due to the characteristics of high melting point, high hardness, excellent wear resistance, excellent thermal conductivity and low thermal expansion coefficient, molybdenum rods become one of the ideal materials for manufacturing precision instruments and equipment.

The application of molybdenum rods in precision instruments and equipment includes but not limited to the following aspects:

Thermal management: Molybdenum rods can be used as heat conduction materials for thermal management components such as radiators, heat sinks, and heat pipes to effectively control the temperature of equipment.

Conductivity: Due to its excellent electrical conductivity, molybdenum rods can be used to manufacture components such as electrical contacts, electrodes, and conductive connectors to ensure good electrical signal transmission for precision instruments and equipment.

Structural support: Due to its high strength and hardness, molybdenum rods can be used to manufacture structural support components for precision instruments and equipment to provide stable structural support and resistance to deformation.

Vacuum sealing: The low thermal expansion coefficient and excellent sealing performance of molybdenum rods make them very important in vacuum sealing applications, such as vacuum instruments, vacuum tubes, vacuum furnaces, etc.

X-ray protection: Molybdenum has good X-ray absorption properties and can be used to manufacture X-ray protection devices and detectors.

More details of molybdenum or molybdenum alloy products, please visit website: http://molybdenum-alloy.com/index.html

Please contact CHINATUNGSTEN for inquiry and order of molybdenum alloy products:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595