Barium tungsten cathodes may require special cleaning and maintenance during use. Since the purity and electron emission properties of the cathode surface are critical to device performance, regular cleaning can help maintain cathode stability and reliability. Here are some cleaning aspects that may require attention:

Cleaning under vacuum conditions: Since barium tungsten cathodes usually work under vacuum conditions, any cleaning process must be carried out under vacuum conditions to avoid contamination and gas residues. Special cleaning equipment and methods may be required for cleaning the cathode surface under vacuum.

Non-hazardous cleaning agents: Use non-hazardous cleaning agents and solvents to prevent adverse effects on the cathode material and electron emission performance. Selection of an appropriate cleaning agent is critical to ensure that the cathode surface is not damaged.

Anti-static: When cleaning the cathode, it is necessary to pay attention to prevent the accumulation of static electricity, so as not to affect the electron emission performance of the cathode.

Avoid Mechanical Damage: Be careful during cleaning and avoid using tools or methods that may cause mechanical damage. Mechanical damage may affect the surface finish and shape of the cathode, which in turn affects the electron emission performance.

Regular maintenance: Barium tungsten cathodes should be regularly maintained and inspected to ensure their surfaces are clean and smooth. If contamination, gas residue or other dirt is found, appropriate cleaning measures will need to be taken.

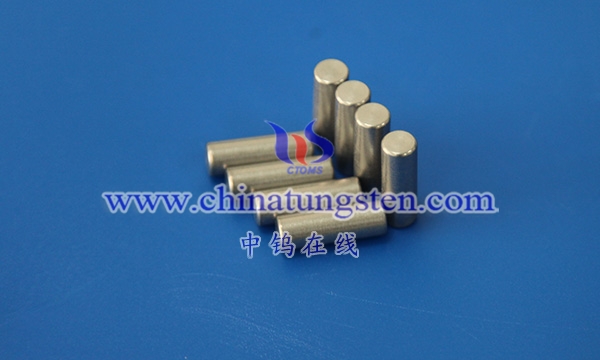

More details of barium tungsten electrode, please visit website: http://tungsten.com.cn/barium-tungsten-electrode.html

Please contact CHINATUNGSTEN for inquiry and order of barium tungsten electrodes:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595