Using tungsten wire in battery manufacturing often involves some specialties, primarily because the batteries need to meet a specific set of properties and requirements. The following are some special features of tungsten wire in battery manufacturing:

High melting point and corrosion resistance: Tungsten wire has an extremely high melting point, which makes it excellent in high-temperature batteries. Some batteries generate high temperatures when operating, such as lithium-sulfur batteries and lithium-air batteries. The high melting point of tungsten wire ensures the stability of the battery in high temperature environments. In addition, tungsten wire is also highly resistant to many chemicals, which contributes to the long-term stability of the battery.

Conductivity: Tungsten wire is a good conductive material, so it can be used to connect electrodes and conductive components in batteries. High conductivity helps the flow of electricity and improves battery performance.

Stability: Battery manufacturing requires material stability because batteries typically need to operate for long periods of time without failure. The physical and chemical stability of tungsten wire makes it an ideal choice for internal components of batteries.

Thin film coating: In some high-performance batteries, tungsten wire may be used as a thin film coating for the electrode material. This coating can improve the performance of electrodes and enhance battery capacity and cycle life.

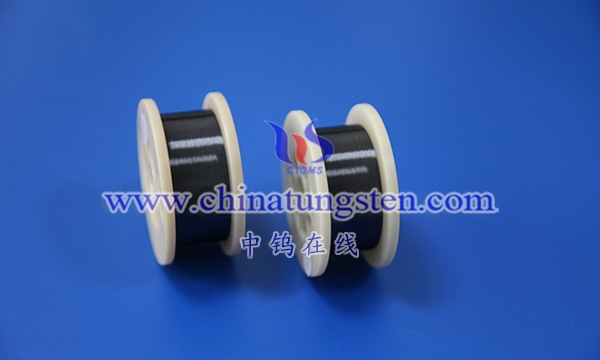

Customizability: Tungsten wire can be custom manufactured to meet the specific requirements of the battery. This means that its shape, size and other characteristics can be adjusted to meet the needs of different types of batteries.

More details of tungsten wire, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten wires.

Email: sales@chinatungsten.com

Tel.: +86 592 5129595