Tungsten wire can often be recycled and reused. Tungsten is a renewable resource, so discarded or used tungsten wire can be processed through recycling methods to extract and recover tungsten. This recycling process has several benefits:

Resource conservation: Tungsten is a rare metal. Recycling and reusing tungsten can reduce dependence on limited resources.

Environmental protection: Recycling tungsten can reduce the environmental impact of mineral mining and tungsten smelting and reduce waste generation.

Cost Savings: Extracting and producing tungsten filament from recycled tungsten is often more economical than starting from virgin ore.

Energy Savings: Smelting new tungsten materials requires a lot of energy, and the recycling process is generally less energy intensive.

Waste tungsten wire is usually recycled through the following steps:

Collection and sorting: Used tungsten wire is recycled and sorted for subsequent processing.

Cleaning and Handling: Tungsten wire may be cleaned to remove contaminants and impurities.

Smelting and Extraction: Tungsten wire is heated and smelted to extract higher purity tungsten metal.

Preparation of new materials: Recycled tungsten metal can be reused to prepare various tungsten products, including tungsten wire.

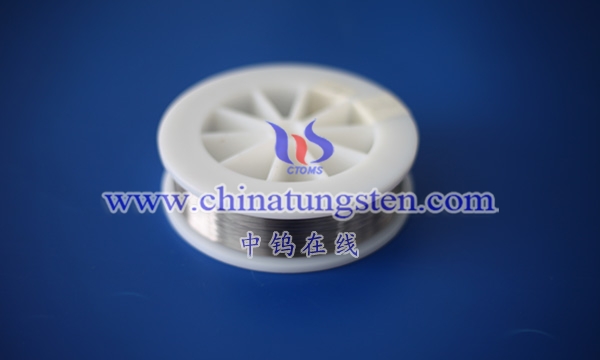

More details of tungsten wire, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten wires.

Email: sales@chinatungsten.com

Tel.: +86 592 5129595