In microelectronic chip manufacturing, tungsten wire is often used as metal bonding wire. These metal connecting lines establish electrical connections between different components inside the chip. Their function is to connect different components of the chip (such as transistors, capacitors, etc.) to the pins of the chip or external circuits. The following are some of the main uses and characteristics of tungsten wire in microelectronic chips:

Electrical connections: Tungsten wire is used to create electrical connections inside microelectronic chips. They connect different components of the chip through tiny solder joints or joints to enable the transmission and connection of electrical signals.

Electrical conductivity: Tungsten has good electrical conductivity, which is its important characteristic in microelectronic chips. Since the current flow in microelectronic chips is usually very small, tungsten wire can provide reliable conductive properties.

Thermal stability: Tungsten wire has a very high melting point, so it can withstand high-temperature processing, such as welding or packaging, during the manufacturing process of microelectronic chips. This ensures connection stability.

Dimensional Accuracy: Tungsten wire can be made into very fine wires, which is critical for the tiny size and high-density layout of microelectronic chips. Their precise dimensions help ensure a precise and reliable connection.

Corrosion Resistance: Tungsten is a chemically inert metal and therefore is not susceptible to chemical corrosion. This allows the tungsten wire to resist contact with other materials without damage during microelectronics manufacturing.

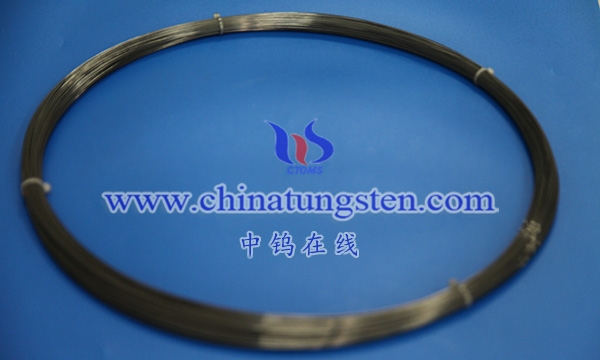

More details of tungsten wire, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten wires.

Email: sales@chinatungsten.com

Tel.: +86 592 5129595