High-density tungsten alloy is a special alloy material consisting of tungsten (W) as the main component and usually contains other alloying elements to improve its performance and characteristics. The “high density” in its name reflects its remarkable high-density properties, which make it widely useful in a variety of industrial applications. The following is a detailed explanation of high-density tungsten alloy, including its composition, preparation, properties, application areas and important characteristics.

- Composition: The main component of high-density tungsten alloy is tungsten, which usually accounts for the majority of the alloy. Tungsten is a chemical element with a very high atomic number. Its atomic number is 74, which is one of the highest elements in nature. High-density tungsten alloys may also contain small amounts of other alloying elements, such as nickel (Ni) and iron (Fe), to improve their properties. These additional elements help enhance the alloy’s mechanical properties and processability.

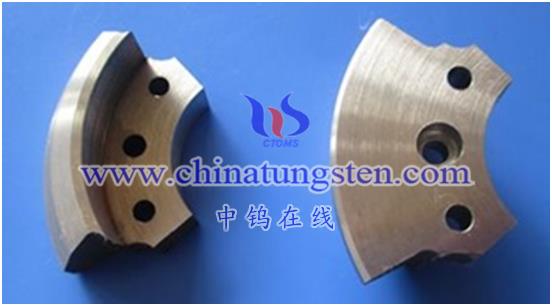

- Preparation: High-density tungsten alloy is usually prepared through powder metallurgy process. The process includes the following steps:

- Powder Preparation: First, pure tungsten powder and powders of other alloying elements (if any) are mixed together to ensure uniform distribution. These powders are usually prepared by ball milling or other mechanical methods.

- Compression: The mixed powder is compressed into the desired shape, usually by hot pressing at high temperatures and pressures. This step helps to bind the powder together tightly.

- Sintering: The compressed shape is sintered at high temperatures, fusing the powder particles together to form a strong, high-density structure. This process also helps eliminate impurities and pores.

- Heat treatment: Some high-density tungsten alloys require heat treatment to improve their properties. This may include heat treatment methods such as annealing or solution treatment.

- Properties: High-density tungsten alloy has a series of excellent properties, including:

- High Density: Tungsten itself has extremely high density and is one of the densest metals in nature. Therefore, high-density tungsten alloy also inherits this characteristic and has very high density. The density of tungsten is about 19.25 grams/cubic centimeter, which is more than twice that of lead and much higher than other general metals.

- High melting point: Tungsten has a very high melting point, approximately 3,422 degrees Celsius (6,192 degrees Fahrenheit), which allows high-density tungsten alloys to maintain stable performance in high-temperature environments. This property makes it ideal for high temperature industrial applications.

- Corrosion resistance: High-density tungsten alloy has high resistance to corrosion and therefore can maintain its performance in some harsh environments. This corrosion resistance is an important advantage in areas such as nuclear engineering and medical equipment.

- Mechanical properties: High-density tungsten alloy has excellent mechanical properties, including high hardness, high strength and excellent wear resistance. Its hardness usually reaches above HRC 25 on the hardness scale.

- Application fields: High-density tungsten alloy is widely used in many fields, including:

- Aerospace industry: Used in aerospace components such as aircraft, rockets and satellites, such as balance masses, aircraft parts and radiation shielding materials. For example, high-density tungsten alloys used in aircraft wing balance weights provide the necessary mass balance to ensure aircraft stability and flight performance.

- Medical field: Used in various parts and components of radiation therapy equipment, MRI machines and medical radiation shielding materials. In medical devices, high-density tungsten alloys can be used to create components with higher density for precise radiation therapy and image acquisition.

- Nuclear Engineering: Used in nuclear reactor components, nuclear power plant equipment and radiation protection materials. The high density and corrosion resistance of tungsten alloys make them ideal for use in the nuclear energy sector, where they can be used to create components inside nuclear reactors while being able to withstand high temperatures and radiation conditions.

- Scientific research: Various components used in particle accelerators, experimental devices and scientific research equipment. In the field of scientific research, high-density tungsten alloys can be used to create sophisticated experimental equipment to study the behavior of atomic and subatomic particles.

- Industrial: Used in high-temperature industrial equipment, high-density tools and wear-resistant parts. In the industrial field, high-density tungsten alloys can be used to manufacture parts that are resistant to high temperatures and high wear, such as nozzles, hammer heads, and tool blades.

- Aerospace field: used in various components of space probes, such as missile components, nozzles and masses. High-density tungsten alloys can provide the necessary mass and radiation shielding in space to ensure spacecraft stability and safety.

- Important features: Some important features of high-density tungsten alloy include:

- Radiation Shielding: Due to its high density, high-density tungsten alloys are very useful in the field of radiation protection and can be used to reduce the spread of radiation. In medical equipment, it can be used to make X-ray radiation shielding parts to protect medical staff and patients.

- High Temperature Strength: It maintains stable performance in high temperature environments and hence is very useful in high temperature applications. In nuclear engineering, high-density tungsten alloys can be used to create internal parts of nuclear reactors to withstand high temperatures and radiation conditions.

- Corrosion Resistance: Due to its corrosion resistance, it can be used in the manufacture of corrosion resistant components. In the chemical industry, high-density tungsten alloys can be used to manufacture equipment components that are resistant to acid and alkali corrosion.

In summary, high-density tungsten alloy is a special alloy material known for its high density, high melting point, corrosion resistance and excellent mechanical properties. It has wide applications in many fields such as aerospace, medical, nuclear engineering, scientific research and industry, and is one of the important materials in modern engineering and technology. Its high density and superior properties allow it to play a key role in a range of high-performance applications.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595