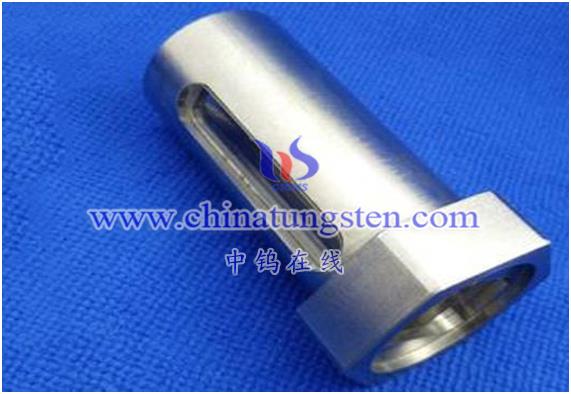

High-density tungsten alloy nozzle is a key component used in high-temperature and high-pressure environments such as aerospace, aerospace engines and rocket engines. It is a jet device used to direct a high-speed fluid (usually fuel or oxidizer) through it to accelerate the fluid and generate thrust to propel an aircraft or engine.

The main features of high-density tungsten alloy nozzles include:

- High-temperature stability: High-density tungsten alloy has excellent high-temperature stability, so it is suitable for nozzles working in high-temperature environments.

- High-density performance: The high density of high-density tungsten alloy helps increase the density of the nozzle, thereby improving its performance.

- Corrosion resistance: High-density tungsten alloys are generally corrosion-resistant, which is very important for nozzles used in rocket engines because they can be corroded by harmful fuels and oxidizers.

- High hardness: High-density tungsten alloy usually has high hardness, which helps to improve the wear resistance of the nozzle and extend its service life.

High-density tungsten alloy nozzles play a key role in aerospace and aircraft engines, where they are used to control the flow of fuel and oxidizer to produce thrust. These nozzles need to be able to operate in extreme high temperature and pressure environments while maintaining structural integrity and performance. High-density tungsten alloy is one of the ideal materials for manufacturing these nozzles due to its high-temperature stability and high-density properties.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595