Tungsten cleaver is a special tungsten wire product, which is usually used in high-precision and high-stability electronic equipment, such as integrated circuits, transistors, etc. It has the characteristics of high purity, high strength, high temperature resistance, and corrosion resistance, and can be used in harsh environments such as high temperature, high pressure, and strong corrosion.

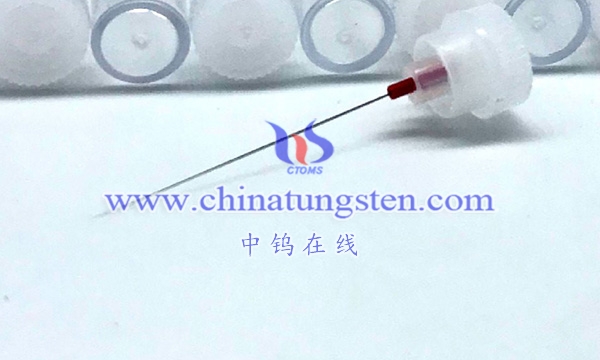

The manufacture of tungsten cleaver requires multiple processes, including material selection, cutting, grinding, polishing, etc. During the manufacturing process, the quality and precision of each process need to be guaranteed to ensure the quality and stability of the final product. The tungsten cleaver is usually made into a slender, sharp shape with a very small diameter and a high degree of smoothness, which can make close contact with the surface of the component under test and obtain accurate signals.

Tungsten cleavers are usually used in the production and testing of electronic equipment, such as integrated circuit packaging, transistor testing, etc. It can be used to test the performance and reliability of electronic components, as well as perform various precision operations and processing. Due to its high precision and stability, the tungsten cleaver has become one of the indispensable and important tools in many fields.

When using a tungsten cleaver, you need to pay attention to safety issues, such as avoiding electric shock and preventing short circuits. At the same time, in order to ensure the accuracy and stability of the test, the tungsten cleaver needs to be maintained and calibrated regularly.

More details of tungsten needles, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595