Metal tungsten wire is a kind of filament made of tungsten, which usually has high melting point, high density, high strength and good electrical conductivity. It is widely used in various electronic devices, such as light bulbs, electron tubes, transistors, etc., as filaments and heating elements. In addition, metal tungsten wire is also used in the manufacture of high-speed cutting alloy steel, super-hard molds and other fields.

Tungsten is a refractory metal with high density, high strength and high hardness. These characteristics require tungsten wire to go through multiple processes during the manufacturing process to ensure its quality and stability. In the manufacturing process, material selection is a very important link. Usually, metal tungsten wire uses high-purity tungsten powder or tungsten strips as raw materials. These raw materials need to undergo strict testing and control to ensure their quality and stability.

Smelting is another important step in manufacturing tungsten metal wire. During the smelting process, tungsten needs to be heated to high temperatures to melt into a liquid state. This process requires the use of specialized smelting equipment and a protective atmosphere to ensure that the tungsten is not oxidized or reacts with other elements. During the smelting process, tungsten also needs to be removed from impurities and added with alloying elements to adjust its properties and structure.

An ingot is an ingot formed by casting the smelted tungsten liquid. This process requires controlling the cooling rate and temperature gradient to ensure that the structure and performance of the tungsten ingot meet the requirements.

Extrusion is the process of extruding tungsten ingots into a certain shape through a die. This process requires controlling parameters such as pressure and temperature to ensure that the extruded tungsten wire has the required shape and size.

Drawing is a process in which the extruded tungsten wire is continuously drawn through multiple die holes. This process requires controlling parameters such as drawing speed, die hole diameter and lubrication conditions to ensure that the tungsten wire has the required diameter and surface quality.

The manufacturing of metal tungsten wire requires multiple processes, and each process requires strict quality control and technical requirements. Only in this way can high-quality and high-stability metal tungsten wires be manufactured to meet the needs of different fields.

Metal tungsten wire is widely used. In addition to its application in electronic equipment, it is also widely used in aerospace, nuclear industry, high-speed cutting and other fields. In the aerospace field, metal tungsten wire is used to manufacture high-temperature furnaces, aerospace engine parts, etc. In the nuclear industry, metal tungsten wire is used to manufacture nuclear fuel elements and reactor components. In the field of high-speed cutting, metal tungsten wire is used to manufacture superhard tools and molds.

With the continuous advancement and development of science and technology, the application fields of metal tungsten wire are also constantly expanding. In the future, with the continuous emergence and application of new materials and new technologies, the application prospects of metal tungsten wire will be even broader.

In short, metal tungsten wire is a very important metal material with wide application value and development prospects. Its manufacturing requires multiple processes and technical requirements, and each process requires strict quality control and technical requirements. Only in this way can high-quality and high-stability metal tungsten wires be manufactured to meet the needs of different fields.

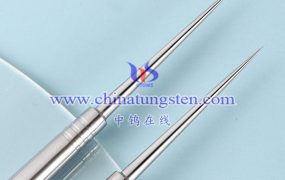

More details of tungsten needles, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595