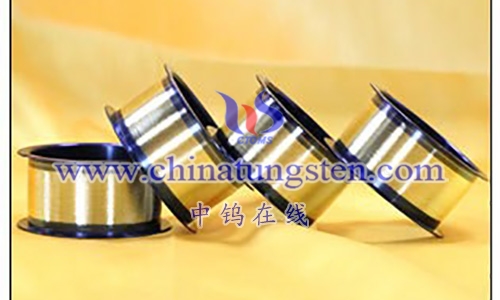

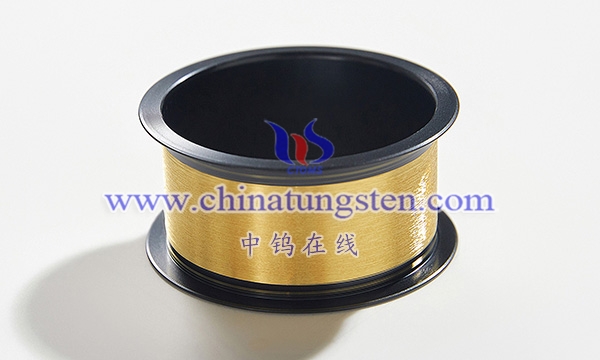

Gold plated tungsten wire is achieved by covering the surface of the tungsten wire with a layer of metal (usually gold). The purpose of gold coating can be to improve the performance of the tungsten wire, increase its electrical conductivity, improve corrosion resistance, or add some special properties in special applications. The main characteristics and applications of gold-plated tungsten wire are:

Improved electrical conductivity: Gold is a good conductive material. By plating gold on the surface of the tungsten wire, the electrical conductivity of the tungsten wire can be improved. This may be important for certain applications requiring high conductivity, such as electronic device manufacturing.

Improved corrosion resistance: The metal coating can provide a layer of protection and increase the corrosion resistance of the tungsten wire, making it more suitable for use in some harsh environments, such as chemical laboratories or high temperature and high humidity conditions.

Appearance improvement: Metal coating can change the appearance of the tungsten wire, making it look more textured, while providing a layer of protection from oxidation of the tungsten wire.

Application fields: Gold-plated tungsten wire may be used in some special fields, such as vacuum electronic devices, semiconductor manufacturing, optical equipment, etc. In these areas, requirements for electrical conductivity, corrosion resistance and appearance may be high.

Of course, the specific properties and applications may depend on the thickness of the coating, the type of metal, and the specific area in which the product is used.

More details of tungsten needles, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595