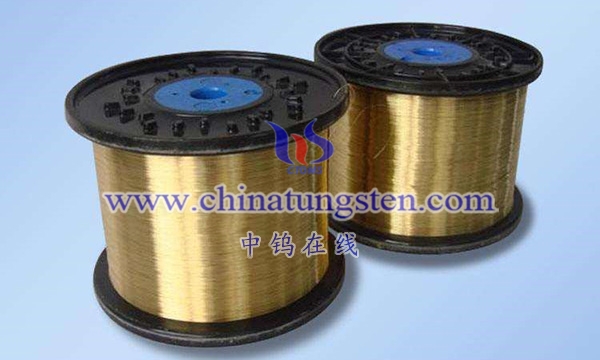

The production process of gold-plated tungsten wire mainly includes the following steps:

1. Tungsten wire preparation: First prepare tungsten wire, usually pure tungsten wire is used as the base material.

2. Surface treatment: Surface treatment of tungsten wire, including cleaning, degreasing and drying, etc., to ensure the quality of the coating.

3. Gold plating treatment: Put the tungsten wire into the gold plating solution, and deposit a layer of gold on the surface of the tungsten wire through electrolysis or other methods.

4. Gold plating layer treatment: After the gold plating treatment is completed, the gold plating layer is further processed, such as heat treatment, polishing, etc., to optimize its performance and appearance.

5. Quality inspection and packaging: Conduct quality inspection on gold-plated tungsten wire, including inspection on appearance, size, coating thickness, corrosion resistance, etc., to ensure that product quality meets requirements. The qualified gold-plated tungsten wire will be packaged for delivery.

It should be noted that the production process of gold-plated tungsten wire is relatively complex, and the parameters and process conditions of each production link need to be strictly controlled to ensure that the quality and performance of the final product meet the requirements. In addition, the production cost of gold-plated tungsten wire is relatively high and the price is relatively expensive. Therefore, in actual applications, it needs to be selected and used according to specific needs and budget.

More details of tungsten needles, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595