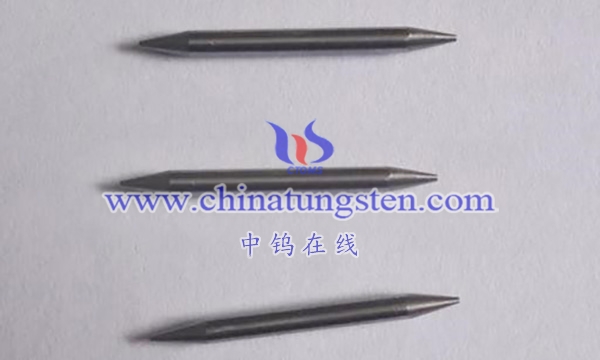

Tungsten pin for vacuum equipment refers to tungsten needle-shaped tools used in equipment and applications in vacuum environments. These tungsten pins typically have high melting points, corrosion resistance, and high hardness, allowing them to maintain stability and performance under vacuum conditions.

Here are some key features and applications:

1. High melting point: The melting point of tungsten is very high, about 3422 degrees Celsius (6192 degrees Fahrenheit), which allows tungsten pins for vacuum equipment to work stably in high-temperature vacuum environments.

2. Thermal conductivity: Tungsten has high thermal conductivity, which helps dissipate or absorb heat in a vacuum environment and prevent overheating.

3. Corrosion resistance: In vacuum equipment, various gases and chemicals are sometimes involved, so tungsten pins for vacuum equipment usually have good corrosion resistance.

4. Vacuum equipment application: This tungsten pin is mainly used in vacuum equipment, such as vacuum tubes, vacuum electronic devices, vacuum heating furnaces, etc. In these devices, tungsten pins can be used for contacts, electrodes, heating elements, etc.

5. Electronic device manufacturing: Tungsten pins play an important role in the manufacturing process of electronic devices such as vacuum tubes, electron beam welding, and vacuum arc.

Since the vacuum environment has high requirements on material performance, the selection of tungsten pins for vacuum equipment usually takes into account its stability and corrosion resistance under high temperature and high vacuum conditions. The manufacturing and processing of these tungsten pins requires a high degree of process control to ensure their reliability and performance in vacuum equipment.

More details of tungsten needles, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595