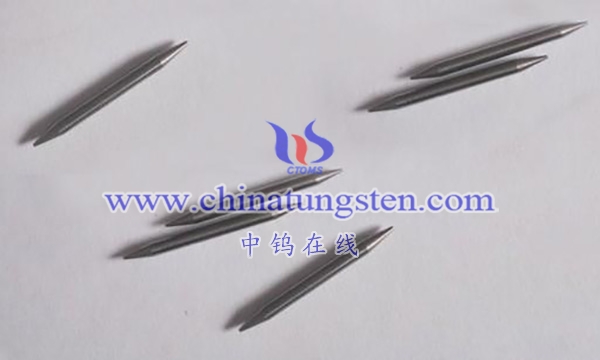

Tungsten needles for chemical reactions refer to tungsten needle-shaped tools used to operate in chemical reactions. These tungsten needles typically require a certain level of corrosion resistance, high temperature stability, and chemical stability to accommodate reaction environments involving harmful chemicals.

Here are some key features and applications of tungsten needles for chemical reactions:

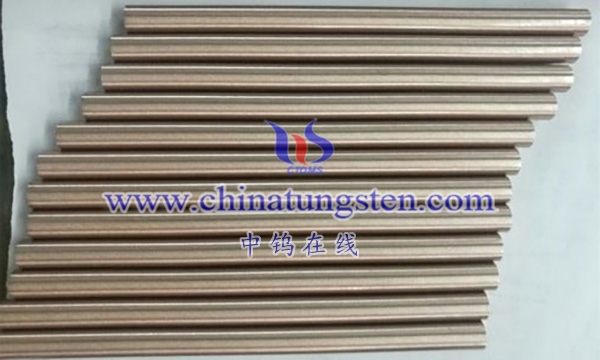

- Corrosion resistance: Chemical reactions may involve corrosive substances such as acids, alkalis, and salts, so tungsten needles used for chemical reactions usually need to have good corrosion resistance.

- High-temperature stability: The high melting point and high-temperature stability of tungsten enable tungsten needles for chemical reactions to maintain structural stability under high-temperature conditions.

- Electrical conductivity: Tungsten is a good conductive material, which may be an advantage in some chemical reactions that require the participation of electric current or electrodes.

- Chemical reaction applications: Tungsten needles for chemical reactions are mainly used in chemical reactions involving harmful or high-temperature and high-pressure conditions, such as experiments in laboratories, reaction equipment in industrial production, etc.

- Catalyst support material: Tungsten needles may be used as catalyst support materials in some catalytic reactions, where their shape and structure can affect the performance of the catalyst.

In chemical reactions, the design and selection of tungsten needles usually depend on the specific reaction conditions, requirements and application scenarios. Due to some of its superior properties, tungsten may be an ideal tool or catalyst support material in certain chemical reactions.

More details of tungsten needles, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595