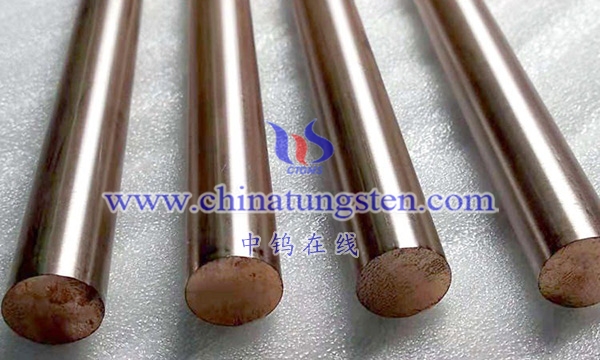

Tungsten pin is a tool used for catalytic reactions. Its main function is to support the catalyst and provide a reaction surface. Such tungsten pins are usually designed in elongated shapes to provide high surface area and good reactivity in catalytic reactions.

Here are some key features and applications:

1. High surface area: The elongated shape of the catalyst support material tungsten pin helps provide a large surface area, which is crucial for reactivity in catalytic reactions.

2. High-temperature stability: Tungsten’s high melting point and high-temperature stability enable it to maintain structural stability during high-temperature catalytic reactions.

3. Thermal conductivity: Tungsten has high thermal conductivity, which helps to effectively transfer and dissipate heat during catalytic reactions.

4. Corrosion resistance: In some catalytic reactions, the reactants or reaction conditions may cause corrosion, and the catalyst support material tungsten pin usually needs to have a certain degree of corrosion resistance.

5. Catalytic reaction applications: Catalyst support material tungsten pins are mainly use

d in various catalytic reactions, such as oxidation reactions, hydrolysis reactions, hydrogenation reactions, etc. These reactions may involve organic synthesis, fuel production, environmental protection and other fields.

6. Nanoparticle Support: Catalyst support material tungsten pins may be designed to support nanoparticles, which may be the active part of the catalyst.

These tungsten pins play a key role in catalyst design and application, helping to improve the efficiency and selectivity of catalytic reactions. Their special shape and material properties make them suitable for a range of catalytic reaction conditions and can be customized to specific reaction needs.

More details of tungsten needles, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595