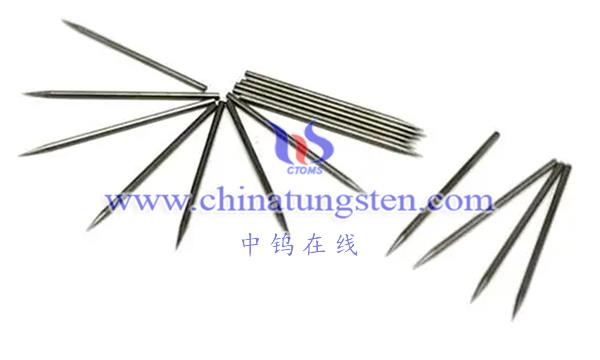

Tungsten carbide needles refer to needle-like items made of carbide, usually tungsten alloy. Cemented carbide is a metal material composed of a mixture of tungsten, cobalt and other metal elements. This alloy is known for its high hardness, wear resistance, and strength, so it is often used when manufacturing tools and components that require wear resistance, high strength, and high hardness.

Here are some possible application scenarios for tungsten carbide needles:

1. Cutting tools: Carbide needles are often used to make cutting tools such as cutters, milling cutters, and drill bits. Their high hardness and wear resistance allow these tools to stay sharp during cutting and machining processes.

2. Abrasive Tools: Needle-shaped objects made of carbide can be used in abrasive tools such as grinding wheels and grinding tools.

3. Drill bits: The wear resistance and high hardness of carbide make it an ideal material for making durable drill bits.

4. Metal processing tools: In the metal processing process, carbide needles can be used to make various tools, including knives, planers, etc.

5. Mining and exploration tools: Needle-shaped tools made of carbide have certain applications in mining and geological exploration, such as core drill bits.

Tungsten carbide is usually composed of tungsten carbide (such as WC) and cobalt (Co). Together, these two components give cemented carbide its unique properties. Tungsten carbide provides hardness, while cobalt adds toughness to the alloy. This alloy is designed to balance hardness and toughness to meet the requirements in specific applications.

More details of tungsten needles, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595