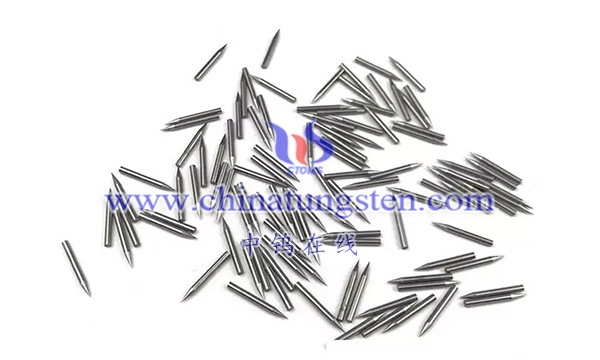

Argon arc welding tungsten pin refers to the welding electrode used in the argon arc welding process, usually made of tungsten or tungsten alloy. Argon arc welding is a commonly used gas shielded arc welding process in which argon is used as a shielding gas to prevent the welding area from being contaminated by oxygen and nitrogen in the atmosphere.

Here are some key features and applications:

1. Material: Tungsten arc welding pins are usually made of pure tungsten or tungsten alloy. Pure tungsten pins have good stability for DC TIG welding, while tungsten alloys may be more suitable for AC TIG welding.

2. High melting point: The high melting point of tungsten enables the argon arc welding tungsten pin to remain stable under high temperature conditions.

3. Electrical conductivity: Tungsten is a good conductor of electricity and is suitable for use as an electrode during welding.

4. Corrosion resistance: Tungsten pins usually have certain corrosion resistance and can maintain stability in the welding environment.

5. AC welding: For AC TIG welding, tungsten alloys may be more common, with added alloying elements (such as molybdenum or niobium) helping to improve the performance of the electrode and reduce arc drift.

6. Application fields: Argon arc welding tungsten pins are mainly used in argon arc welding processes, including welding stainless steel, aluminum and their alloys and other materials. This welding process is commonly used in applications that require high quality, high appearance, and low porosity.

More details of tungsten needles, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595