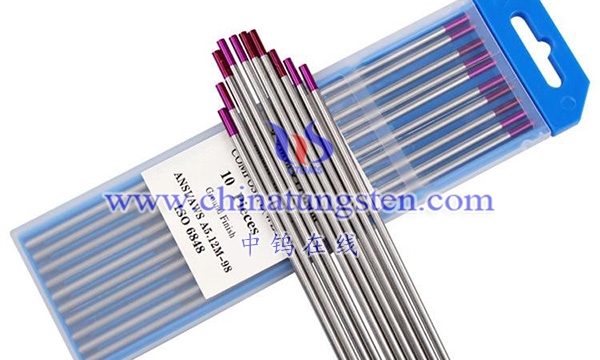

Electrostatic discharge tungsten needle usually refers to the tungsten needle used in Electrical Discharge Machining (EDM). Electrical discharge machining is a non-traditional machining method that converts electrical energy into heat to remove material. In this process, the electrodes typically use tungsten or a tungsten alloy, and a tungsten needle may be part of the electrode.

Here are some of the key features and applications related to electrostatic discharge tungsten needles:

1. High melting point and high temperature resistance: Tungsten has an extremely high melting point and excellent high temperature resistance, allowing it to withstand extremely high temperatures during the spark discharge process.

2. Electrical conductivity: Tungsten is an excellent conductive material, which is crucial for conducting current to the discharge area in EDM.

3. Corrosion resistance: Electrostatic discharge tungsten needles need to have good corrosion resistance because they may be subject to certain chemical erosion during processing.

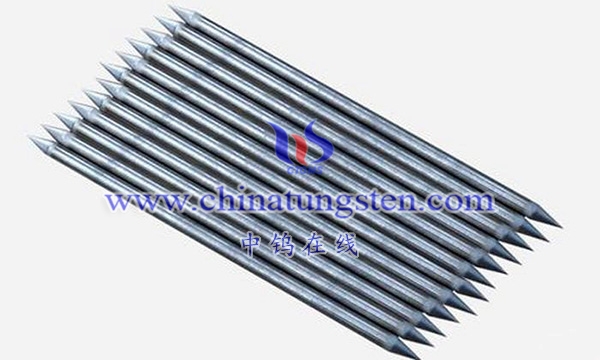

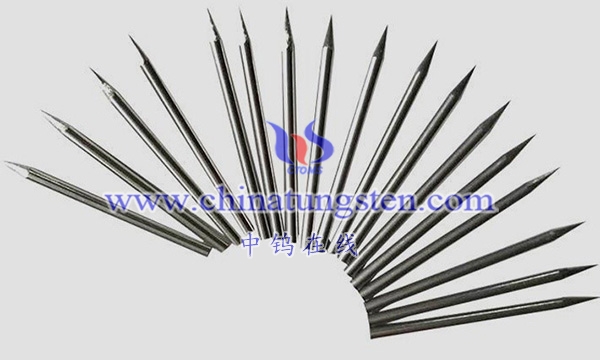

4. Sharpness: The sharpness of the tungsten needle is very important for focusing the current and accurately removing material during the discharge process.

5. Precision machining: Electrostatic discharge machining is often used to manufacture precision parts, so the accuracy and stability of the tungsten needle are crucial to obtaining high-quality machining results.

Electrical discharge machining is widely used in the manufacturing industry, especially where high-precision machining of metals, alloys or conductive ceramics is required. In these applications, the electrostatic discharge tungsten needle plays a key role as part of the electrode.

More details of tungsten needles, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595