Tungsten wafer test probe is a key tool for semiconductor wafer testing. Its main function is to contact the chips or devices on the wafer during the testing process to obtain its electrical performance and reliability. The data. The following will introduce in detail the manufacturing process, structure, function and application of tungsten wafer test probes.

1. Manufacturing process

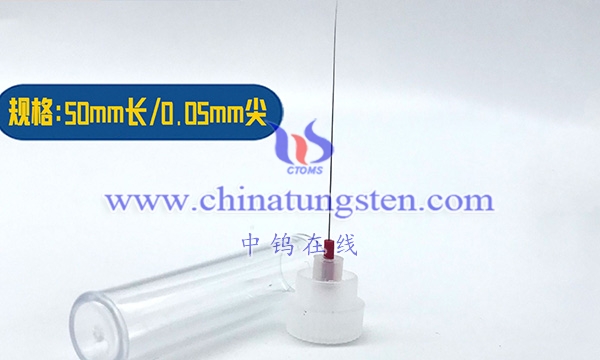

The manufacturing of tungsten test probes for wafer testing requires a series of precise machining and surface treatment processes. First, high-purity tungsten material is selected and processed into slender needle shapes through cutting and grinding processes. Then, heat treatment and surface treatment are performed to enhance its hardness and corrosion resistance. During the manufacturing process, the requirements for dimensional accuracy and geometric tolerances are very strict to ensure good contact between the probe and the wafer without causing damage to the wafer.

2. Structural characteristics

The structure of wafer testing tungsten test probe usually includes three parts: needle head, needle body and needle tail. The tip part is the part of the probe that contacts the wafer, usually in a tapered or spherical shape to reduce contact resistance and improve signal transmission efficiency. The needle body is the main part of the probe and usually has a certain degree of curvature to ensure the rigidity and stability of the probe. The pin tail part is the connection part of the probe, which is usually connected to the test instrument to transmit test signals and control the movement of the probe.

3. Functional features

Wafer testing tungsten test probe has the following functional features:

1. High strength and high hardness: Tungsten is a metal material with high strength and hardness, so the wafer testing tungsten test probe has high tensile strength and wear resistance, and can withstand high load and high frequency testing.

2. Good conductivity: Tungsten is a good conductive material, so the wafer testing tungsten test probe has good conductivity and can ensure the accuracy and reliability of test data.

3. Corrosion resistance: Tungsten is a metal material with stable chemical properties and is not easily oxidized and corroded. Therefore, the wafer testing tungsten test probe can be tested under various environmental conditions.

4. High precision and high stability: The manufacturing process of the wafer testing tungsten test probe is strict, and the dimensional accuracy and geometric tolerance requirements are very high. Therefore, it has high precision and high stability, which can ensure the accuracy and repeatability of the test results.

5. Reusable: Since the wafer testing tungsten test probe uses tungsten material, and tungsten is a metal material that is not easily worn and deformed, it can be used multiple times and has a high service life.

More details of tungsten needles, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595