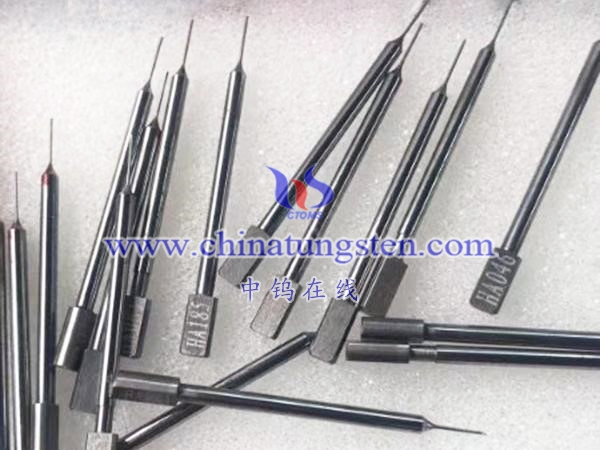

Tungsten carbide needle is a needle-shaped object made of tungsten alloy. Tungsten alloys usually contain alloys of tungsten, nickel, iron and other elements. The content of tungsten is relatively high, which gives the alloy high hardness and high melting point. Tungsten alloys are widely used to make a variety of tools and parts, including needle-shaped items, due to their hardness and wear resistance.

Tungsten carbide needles may be used in a variety of applications, depending on how they are prepared and alloy composition. Some common applications include:

1. Industrial cutting tools: Tungsten carbide needles can be used to make cutting tools, such as blades, milling cutters, drill bits, etc. Its hardness and wear resistance make it suitable for areas where tool durability and cutting quality are critical.

2. Molds and mold parts: Tungsten carbide needles are also commonly used in the manufacture of molds, where high hardness and wear resistance are required. These molds can be used in manufacturing processes such as molding and injection molding.

3. Medical devices: Tungsten carbide needles may be used in some medical devices, such as surgical tools or other medical equipment that require precision and durability.

4. Precision instrument parts: Due to the high density and hardness of tungsten alloy, tungsten carbide needles can be used to manufacture some instrument parts that require high precision and stability.

It is important to note that the properties and uses of specific tungsten carbide needles may vary depending on preparation methods and alloy composition. When selecting and using tungsten carbide needles, the appropriate selection should be made based on the specific application needs and the specifications provided by the manufacturer.

More details of tungsten needles, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595