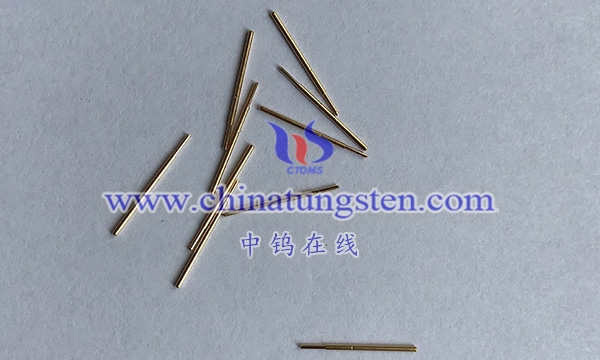

Tungsten carbide needles can be divided into the following types according to different characteristics and uses:

1. Straight needle: It is the most common type of tungsten carbide needle, mainly used to process small parts, such as adjusting instrument panels, disassembling switches, etc.

2. Elbow needle: It is a tungsten steel lathe needle with a curved head. The head can be a 90-degree elbow or a 180-degree elbow. This kind of needle is mainly used for processing deeper or harder-to-reach parts.

3. Ball-end needle: A ball-end needle is a tungsten carbide needle with a hemispherical end. This kind of needle can better adapt to the needs of curved surface processing.

4. Taper shank lathe: It is a drill bit similar to that used in machining. Its head is tapered and is mainly used for processing tapered holes or tapered surfaces.

5. Thread bur: It is a bur specially used for processing threads. Its end can be straight or with an elbow at a certain angle.

6. Cutting needle: It is a tungsten carbide needle specially used for cutting materials. Its end can be straight or with an elbow at a certain angle.

7. Chamfering needle: It is a tungsten carbide needle specially used for chamfering. Its end can be straight or with an elbow at a certain angle.

8. Trimming needle: It is a tungsten steel bur specially used for trimming materials. Its end can be straight or with an elbow at a certain angle.

The above are some common types of tungsten carbide needles. Each type of tungsten carbide needle has its specific application scenarios and uses. When selecting tungsten carbide needles, you need to choose based on actual needs and processing requirements.

More details of tungsten needles, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595