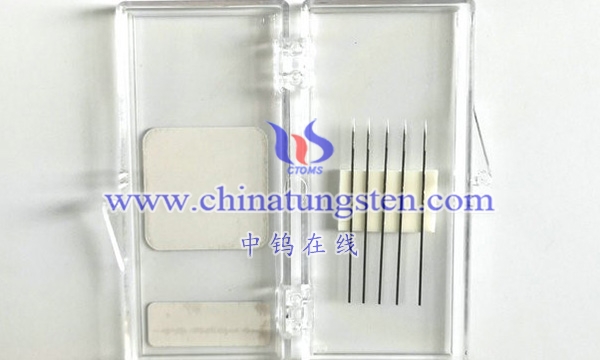

Application of straight tungsten needle for wafer testing

Straight tungsten needles are mainly used during integrated circuit wafer testing to test the electrical characteristics of each die on the chip. During the test process, the probe needle contacts each die on the chip and conducts electrical characteristic testing by transmitting signals to detect defects and problems on the chip. By using wafer testing straight tungsten pins, you can ensure that the quality and performance of each die meet the requirements, improving the yield and reliability of the chip.

Wafer testing straight tungsten needle is one of the indispensable detection tools in integrated circuit wafer testing. It is made of tungsten material and has the characteristics of high rigidity, high conductivity and long life. It is suitable for testing various sizes and types of integrated circuit wafers. By using wafer testing straight tungsten pins, you can ensure that the quality and performance of each die meet the requirements, improving the yield and reliability of the chip. With the continuous development of integrated circuit technology, the requirements for straight tungsten needles for wafer testing are becoming higher and higher. In the future, research and innovation will continue to improve manufacturing processes and improve performance indicators.

More details of tungsten needles, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595