Customizing tungsten probes for wafer testing is a comprehensive process that requires consideration from many aspects, including design, material selection, manufacturing process, quality control, environmental protection and customer service. The importance of these aspects will be explained in detail below:

1. The importance of design

• Meet specific needs: Customers’ testing needs can vary widely, so the design phase is critical. The sharpness, shape, material, etc. must be customized according to the actual situation.

• Adapt to diverse markets: The demands for test probes in different industries and application fields vary greatly. Through design flexibility, manufacturers can meet the needs of diverse markets.

2. The importance of material selection

• Performance requirements: Different testing environments and applications may have different requirements for the material performance of the probe. For example, high temperature resistant materials are required in high temperature environments.

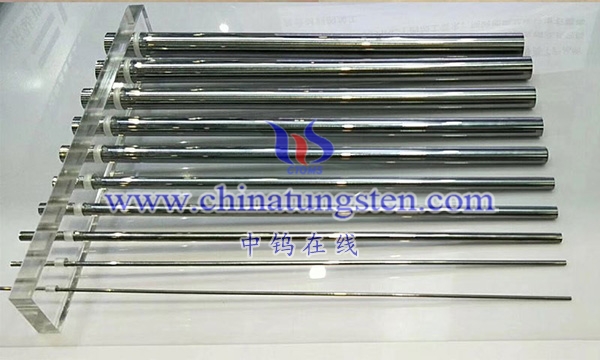

• Electrical conductivity: Tungsten or tungsten alloys are often chosen for their excellent electrical conductivity properties, which are critical to the accuracy of the test.

3. Influence of manufacturing process

• High-precision manufacturing: The manufacturing process requires high precision to ensure that the tip of the probe meets the design requirements and can accurately establish electrical connections with the test points.

• Mass production feasibility: The manufacturing process needs to be of sufficient scale to meet the needs of mass production.

4. The necessity of quality control

• Consistency: In large-scale production, maintaining consistency from probe to probe is key. Quality control systems need to ensure the stability of product quality.

• Compliance certification: Carry out corresponding certifications for compliance standards that may exist in different industries to ensure product compliance.

5. Trends in environmental protection and sustainability

• Social responsibility: More and more companies are paying attention to social responsibility and improving corporate sustainability through the use of environmentally friendly materials and processes, as well as recycling designs.

• Market trends: The market demand for environmentally friendly products is gradually increasing, and products with environmentally friendly characteristics are more competitive in the market.

6. The criticality of customer service and communication

• Customer Satisfaction: Customer satisfaction can be improved by maintaining close communication with customers and resolving issues promptly.

• Changes in requirements: Customer needs may change during the customization process, and timely communication helps adapt to changes.

7. Drive for updates and improvements

• Technology leadership: Wafer testing tungsten probes are a technology-intensive field. Through continuous updates and improvements, we maintain the technology leadership of our products.

• Market Competition: In a rapidly evolving market, continuous product improvement helps to remain competitive.

More details of tungsten needles, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595