The main functions of ultrafine tungsten manipulator probes are as follows:

1. Testing the hardness of materials: Tungsten probes are often used to test the hardness of materials. The hardness of a material is determined by pressing into the surface of the sample and measuring the depth of the indenter. This method can be used to determine the hardness of metals, plastics, rubber and other materials, helping manufacturers determine the quality and reliability of their products.

2. Detecting material composition: Tungsten probes can also be used to detect material composition. By analyzing the composition of tiny areas on the surface of a sample, the chemical composition and proportions of the material can be understood.

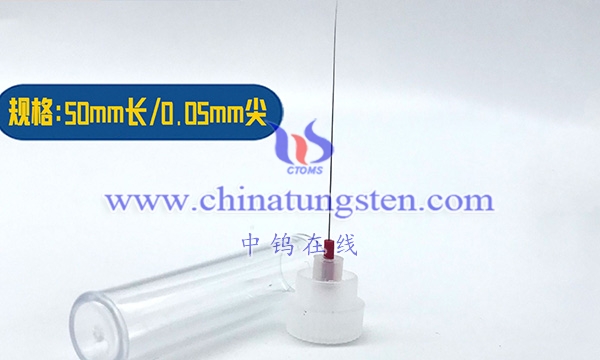

3. Micro area analysis: Because the tungsten probe has an elongated shape and a sharp tip, it can easily analyze small areas. For example, in geology, tungsten probes can be used to detect the hardness and composition of underground rocks; in medicine, tungsten probes can be used to detect the hardness and structure of internal tissues of the human body.

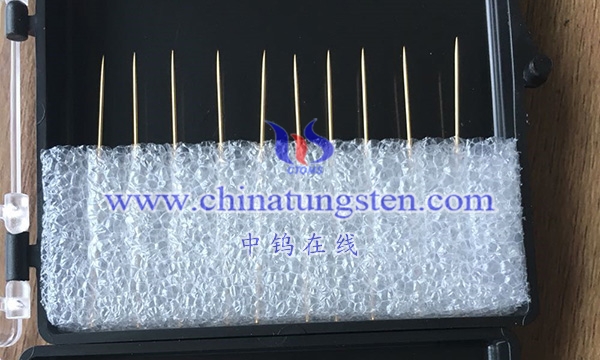

4. Electrode material: Tungsten probes are often used as electrode materials due to their high melting point and good electrical conductivity. For example, in semiconductors, optoelectronic devices and vacuum electronic devices, tungsten probes can be used as electrodes, lead materials, heaters or grids, etc.

5. Wafer testing or chip IC detection probes: According to different electronic testing purposes, tungsten probes can be divided into microelectronic test probes (wafer testing or chip IC detection probes).