The manufacturing process of Chinatungsten Online’s high-density tungsten alloy drone counterweight mainly includes the following steps:

- Raw material preparation: The raw materials required to prepare high-density tungsten alloy include tungsten powder, nickel powder, iron powder, etc. These raw materials need to undergo strict screening, drying, mixing, etc. to ensure their quality and stability. Among them, the particle size and purity of tungsten powder have an important impact on the performance of high-density tungsten alloy.

- Press molding: Put the mixed raw materials into the mold and press them under a certain pressure and temperature to obtain the required shape and size of the weight block. During the press molding process, it is necessary to pay attention to controlling factors such as pressure, temperature and time to ensure that the shape and size of the weight block meet the requirements and have sufficient strength and stability.

- Sintering treatment: The pressed weight block needs to be sintering to make it have sufficient strength and stability. The sintering temperature and time need to be strictly controlled according to the formula and process requirements to ensure that the elements in the tungsten alloy are fully diffused and combined, and the required phase structure and microstructure are obtained.

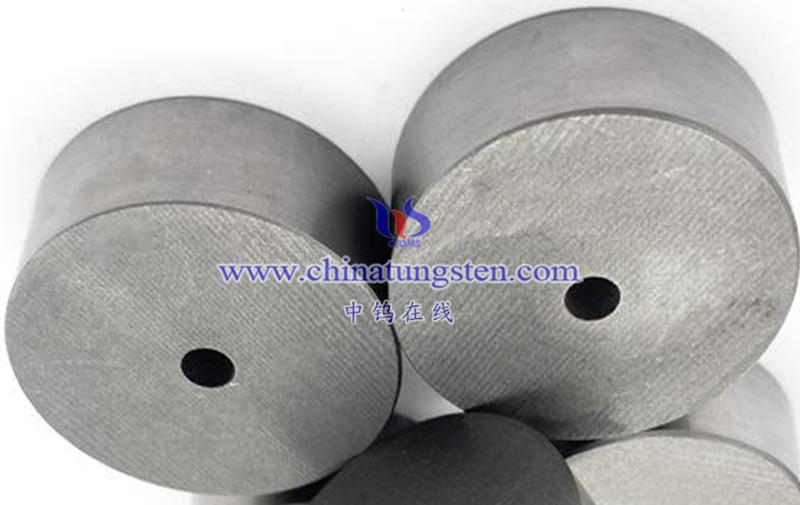

- Processing: The sintered weight block needs to be processed, including turning, milling, drilling, etc., to obtain the required shape, size and accuracy. During the processing process, attention needs to be paid to controlling the processing parameters and tool selection to ensure that the surface quality and accuracy of the counterweight block meet the requirements.

- Quality inspection: The processed counterweight blocks need to undergo quality inspection, including appearance inspection, size inspection, density inspection, etc., to ensure that their quality and stability meet the requirements. During the quality inspection process, attention needs to be paid to controlling measurement errors and data processing to ensure that the quality and stability of the product meet customer requirements.

In short, the manufacturing process of Chinatungsten Online’s high-density tungsten alloy drone counterweights mainly includes steps such as raw material preparation, press molding, sintering, processing and quality inspection. These steps need to be carried out under strict quality control and management. , to ensure product quality and stability.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595